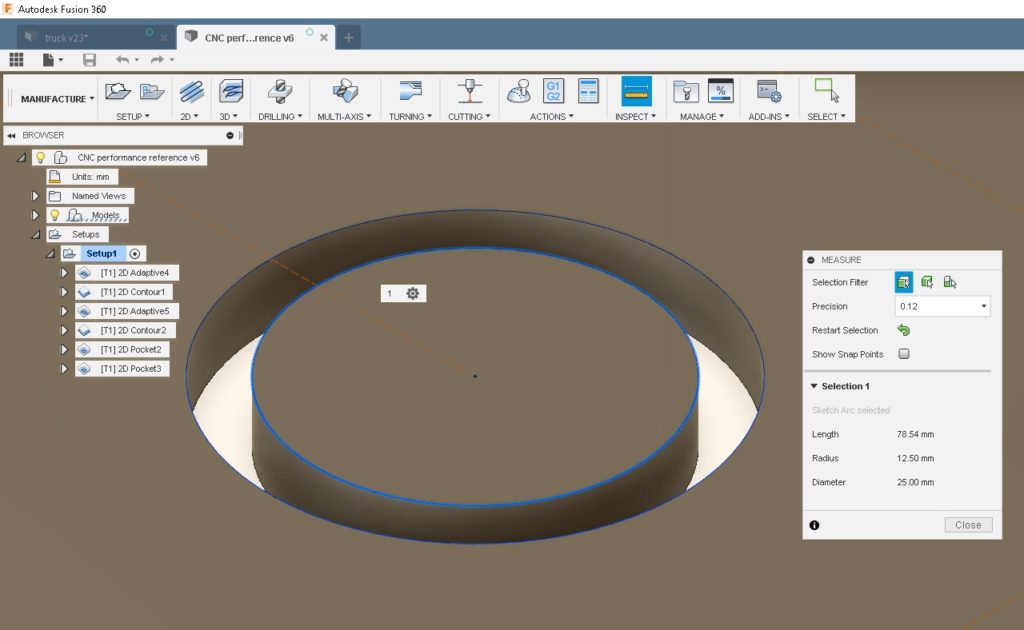

We machined this acrylic disc as a simple initial test.

Time to test Super Gerbil CNC controller accuracy. Using Fusion 360, we designed and machined a simple 25.00mm disc from clear 4.4mm acrylic.

After that, we measured with grandfather’s old micrometer and my verniers.

Both devices reported 25.02mm diameter, a 20 micron error against design.

Next step was to design and machine a matching pocket. My first guess diameter of 25.08mm worked well. It’s beautiful to see the disc slides in smoothly, but doesn’t slip out. Smooth and uniform machining effectively reduces the fit.

These results reflect a good tool-chain:

- Fusion 360

- UGS G-Code Sender

- the Super Gerbil CNC controller

- the Nomad 883 hardware

- new endmill.

In summary we proved the Super Gerbil CNC controller didn’t let the others down.

The Super Gerbil is available for pre-order, with delivery around March-May 2019. Regular updates are on our Kickstarter page.

1 thought on “Super Gerbil CNC Controller Accuracy Testing”