It’s testing time for the Super Gerbil CNC Controller pre-production units! We put them through their paces with a testing regime that’s included a wide range of activities:

- Installation – technically correct and user-friendly

- Configuration – technically correct and user-friendly

- All the basic operations – jogging, homing, returning data to PC etc

- Real world milling jobs – keep an eye on our website, we’ll show them off soon

- Accuracy testing – see our Super Gerbil accuracy blog

- Performance and thermal testing

Nuts and bolts of testing

Product designers suck at robust testing their own product, so Dan’s been taking the lead on testing. Yes, we have found a number of issues, which Paul has worked hard to resolve. 90% of the issues related to the firmware, and many of them are minor. This is encouraging as it means that by the time the product testing completes, the firmware will be very solid.

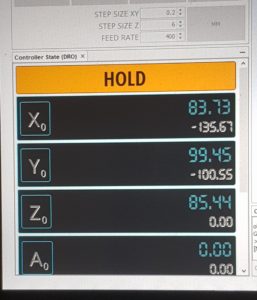

An example firmware issue: although the steppers were moving correctly, Super Gerbil (and hence UGS) reported lagged stepper positions. Sometimes an old stepper position could remain on the PC screen for several seconds after the stepper movement finished. Paul embarked on a forensic analysis of the firmware operation, so now the PC has the latest stepper position. Dan insists on version control of the firmware so that none of the resolved bugs surface again in the future. We logged only two hardware issues. The first relates to a supplier substituting their alternatives for our documented component. Although the unauthorised substitution made only a minor impact, we’ll insist on 100% BOM compliance going forward.

The second issue concerns a supplier’s small documentation error causing unexpected results. Through extensive debugging, Paul identified their documentation error. After a small Super Gerbil circuit change, we now fully support the unique design of TB67S109 stepstick.