When replacing or upgrading your K40’s controller, how do you choose the right option for you? In this K40 controller desktop review, we cover your options.

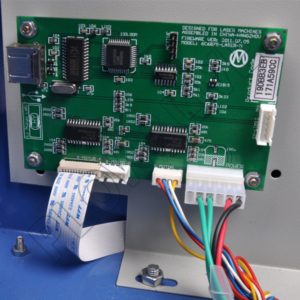

You are here… M2 Nano board

Our K40 controller review starts with the M2 Nano board which looks like this.

It is the standard controller that ships with each K40 laser. It’s just a motion controller which has not been integrated with the K40’s digital control panel for laser power.

Disadvantages include:

- It has very limited control of cutting in corners, which is likely to result in burnt corner points

- It provides only dither-mode engraving. This simply means it can only switch on/off at one set power level, so you miss out on the improved images that gray-scale engraving brings

- It’s expensive for what it is – outdated technology

- It runs an unknown propriety form of G-code, making it hard to work with. The work-around is to use theK40whisperer software which emulates the proprietary G-code so that your K40 can be accessed by software other than MoshiDraw / LaserDraw / CorelDraw.

Things that matter

Before we step through available controllers in this K40 controller review, let’s be clear on what factors matter….

- Ease of upgrade (the technical effort and complexity)

- Engraving and cutting speed

- Quality of the engraved images – gray scale looks better than dithering, and 16 bit is much better than 8 bit.

- 3rd-axis capability – for some users, the ability to control a Z axis table or rotary via G-code can be important

- Support – some products have no support, and you’re reliant on the goodwill/knowledge of the user community. You may prefer a product that has dedicated support provided by the vendor.

- Overall Cost

Comparison Table

[supsystic-price-table id=16]

Details as known at time of publishing.

Technical descriptions

For those interested in the technical details, this section is for you. If not, skip to the Summary.

One of the key differentiators between controllers is their dialect of G-code. One kind is Grbl, an open source firmware. Smoothieware and TinyG are open source firmware derived from Grbl. Both provides G-code motion and laser power control.

DSP based controllers use G-code as input, but are expensive specialized circuits that really belong in their own category.

The K40 controller review list:

Mini Gerbil: a recently designed replacement to a successful Kickstarter project. It uses a powerful (but cost effective) 32 bit Arm processor called STM32. It uses Grbl. The Mini Gerbil has dedicated firmware which optimizes the PWM, speed profiles and the USB communication. It comes in a neat little case.

Super Gerbil: a successful Kickstarter project offering up to 5 axis control for CNC, but is also applicable to lasers. Has all I/O coupled via opto- couplers to reduce electrical interference and noise. Also based on the 32 bit Arm processor STM32 . Uses Grbl. The Super Gerbil has dedicated firmware which optimizes the PWM, speed profiles and the USB communication.

Cohesion3D: these boards are based on the 32 bits LPC1768 ARM processor (dating from 2008). This board runs Grbl and Smoothie, comes with an SD card, display and Z-axis control. Unfortunately, at the time of writing we haven’t found specifications about the PWM resolution and speed.

TinyG: TinyG boards are based on the 8 bits AVR xmega192a3 processor but there’s limited information available. The board runs TinyG which has been derived from Grbl. Unfortunately, at the time of writing we haven’t found specifications about the PWM resolution and speed.

Arduino/Eleksmaker: these boards are based on the Arduino 8bits AVR processor. Their main disadvantage is the 8 bits PWM provides limited levels for laser power control – you won’t get quality gray scale engraving. Uses Grbl.

RUIDA DSP is a digital signal processor board used in the more expensive Chinese Lasers, offering faster motion and laser control than the Nano M2 board. The Ruida DSP controller comes with RDWorks, a CorelDRAW derivative. The only other working software we know of is LightBurn, but be prepared to spend more for the DSP specific version.

Summary

The comparison table reveals a large disparity in value. We suggest the following should be dropped from further consideration:

- the M2 Nano controller – fewer features than cheaper alternatives, with the added disadvantage of limited software being only CorelDraw and Laser Draw.

- DSP – their traditional speed advantage is under threat from the new generation controllers, and they have no other stand out features to justify their extreme cost.

Meanwhile, Arduino and TinyG lag on features. Arduino may work for the very low budget option if you’re prepared for some fiddling without dedicated support, whereas the TinyG doesn’t compete well at all in its price range. Oh, and don’t forget that Arduino’s hardly a speed machine.

Among the remaining, Mini Gerbil is a clear winner in the 2 axis stakes. In the battle for 3 axis controllers, Super Gerbil is a newer, better value product out-staging the older Cohesion 3D.

What have we missed ?

We’ve tried to simplify a relatively complex decision, and this may not take into account everyone’s needs. Who knows, maybe there’s someone out there who actually like CorelDraw ! Seriously though, we see a lot of interest in engraving, but if you’re a cutting-only guy or gal, this could change your best choice.

We didn’t review CNC related boards like PlanetCNC since we have no evidence that these boards are used in K40 laser machines.

If we’ve missed a decision factor of interest, or the summary isn’t quite complete, let us know in the comments below. We’re happy to update the table and blog.

Pssst, have you heard…

It’s no secret we sell the Gerbil products that topped this review. And it shouldn’t be a surprise they’ve come out on top – we purposefully designed them to address the gap between Arduino’s poor performance and features, and the poor value/features of the other products.

Interested in our products ? Here’s the links for Mini Gerbil and Super Gerbil.

My K40 Laser came with a Ketai Gold3 controller board. My laser has the digital display. Unfortunately for me, it will only run on Corel Draw, and the supplier only provided a Chinese version! I tried installing the M 2 nano board, which did not work.

Are you familiar with the Ketai Gold 3 board and if so, will a mini Gerbil work on my machine? Also, what software does it support?

Thank you for providing the overview of controllers.

I’m not familiar with this board but will do some research into it.

From the pictures I can see it’s just a LiHuiyu Studio Labs boards which seems to be identical to the M2 Nano boards. Probably the dongle did not match the internal serial number. All connections are identical so it should work with the Mini Gerbil board. If not, I will refund you in full after returning the board.

How does the Cohesion3D LaserBoard stack up in comparison?

https://cohesion3d.com/shop/controllers/cohesion3d-laserboard/

See column C3D.

You won’t want to hear about this then… runs GRBL and all I had to do was jumper the end stop connector(3 wire) into a dual 2pin endstop cable. And it costs only ~$60 and like C3D it is based on the Smoothieboard so if Grbl isn’t your cup of tea, there’s Smoothieware too.

[link removed by Awesome.Tech]

Some people may copy our designs and IP. Such is life. If you’re a student and funds are thin, I understand you choose the absolute cheapest option. Just be mindful that you’re unlikely to get quality support and customer service, and you won’t have that warm feeling that you’re supporting innovation.

Is the Super Gerbil plug and play with a K40 with a ribbon cable?

I am looking to upgrade the brain of my K40. In the future I want to to do a rotary attachment and a bed height adjustment. It would be a nice to have a built in bed height control in software, but it is nit a need to have. I can electrically but manually adjust that if needed. How would bed height adjustment be handled in software with the super?

How does rotary work with the super vs. the mini.? What does it mean by “rotary plug”? What does the wiring look like for that?

Sorry for all the questions. Links to further reading are appreciated.

Hi Super Gerbil has just screw terminals and no ribbon connector. However i will publish a middle men board for those interested. Maybe even produce a few and make them available on the supergerbil.com The height can be adjusted via the z axis which is integrated into the light burn software. The rotary can be on the y, a or b axis on the Super Gerbil while it plugs into the y axis plug on the Mini Gerbil. Hope this answers your questions.

Hi,need some help,just installed gerbil but i have a couple of issues you may be able to help with,k40 laser,when i hit the home button in lightburn the head runs into the lower left gantry and wont stop,plus BIG issue is when the laser is running it does not alter power % nor does it stop when it rapid moves between items (laser will cut continuously)not going off between letters for example

Best is to post on the K40 forum or email us. It’s likely that the X axis direction is inverted so use $3 to configure this. When the laser does stay on continuously, you have a loose PWM wire or the ground is floating. The latter happens when the power supply is taken out of the k40 case or is loose.

MiniGerbil have cut and engrave possibilities equal or similar as moshidraw?

Hi Alfonso, yes it does and is even better since it allows you do do even gray scale engraving next to dither. The M2Nano board does only dither engraving. Cheers!

Hi, I’ve ordered the gerbil pro pack for my k40 (still waiting on it as I’m uk based) and I’m wondering if there is any way of getting realtime information from this to be displayed on a LCD, will there be support for standalone at any point (sd card based board).

I’m fairly new to the laser game although I am pretty tech savvy with cnc machines as I have a 8ft x 4ft machine so tinkering isn’t the issue but when it comes to lasers I’m not too clued up yet

Hi to keep the product affordable we choose not to add these features. Also the production volume is far too low to make this option viable.

Hope this makes sense, Cheers Paul

Absolutely understand your position 🙂 , shame as it would of made a cool addition to the board, however from the reviews on many forums I must say I’m looking forward to scrapping that crappy m2 board !! It can rot in hell were it belongs ha. One last thing if you dont mind, in the future I want to build a larger scale laser, not huge but bigger than the k40 can hold in its case, will the gerbil still be capable of a larger build ? For example a more powerful laser tube ? Or is it fully configurable

Thanks 🙂

Yes the size of the bed is fully configurable via $130 and $131 settings (up to 2000 meter, not that it would be that big, lol). The laser power range and sensitivity can also be set via the $ configuration settings ($30).

Cheers, Paul

Fantastic 🙂 thanks for the quick replies, my parcel has now landed in the uk 😮 exciting stuff… more looking forward to this board than any other upgrade I’ve purchased . Thanks

Chris how did you get on with this on your machine, easy install etc,

Hi everyone, i have just installed the latest version of Inkscape and the mini gerbil extensions. The raster extension is working fine, but the laser cutting extension gives me this dialog “Traceback (most recent call last):

File “laser.py”, line 48, in

from svgpathtools import *

ImportError: No module named svgpathtools” in the box after hitting apply and it dose not stream of save a g-code file.

Any thoughts.

Thanks.

Sean.

Hi Sean, it seems that the svgpaths library is missing. The k40 forum has a post about this see https://awesometech1.wpengine.com/k40-forum/topic/inkscapes-python-gives-you-issues/

Further on https://github.com/paulusjacobus/awesometech we have these libraries listed. Alternatively you can use a previous version beta7 which does not sort vector paths.

I have a Lightobjects AWC608 controller on my K40 but am finding the software to be pretty useless. If I replace this unit with a mini Gerbil will I still be able to use my front-panel (i.e. offline) controls for moving the head, setting the origin etc?

Hi Nick, I believe LightBurn has a DSP version of their software too. It’s a bit more expensive than the standard G-code licence but it’s worth a try. Our MG unit does not interact with the control display. Sorry I can’t be more helpful. Cheers, Paul

I have a K40 with the NanoBoard. My main concern is I have to set the power to 14% to engrave, and then stand up and set it to 30% to cut.

This has caused many problems for me as sometimes I forget that. If I try to engrave fast enough, the lines will not look nice.

Can mini Gerbil control laser intensity this via software, so I can have the laser set to 30% all the time, and forget about having to stand up every time-

Hi Alonso, Yes Mini Gerbil controls the laser strength (power). You can also adjust it on the fly via the laser software.

Hi Paul,

I’m very interested in a Mini Gerbil for my K40 so I can run lightburn, this is likely a newbie question but can this board run a lightburn camera or is that run separately straight to the PC? Also, can it run a rotary or will I just need to unplug my x-axis and plug in the rotary (HM laser) like I do now? Lastly, it’s great to see fellow Aussies leading the way in innovation, keep up the good work!

The camera does run separately straight to the PC. You can swap the Y axis plug whith the rotary plug (that’s all). Lightburn has a lot of aids and features to help you driving the rotary. Just download the trial version to see if that works for you. Thanks for your comment about innovation, we love that! Cheers Paul and Dan

I think this assessment is somewhat biased by a misunderstanding and over-emphasis on understanding of GCode vs. Lhymicro-gl.

It can cut corners perfectly fine. It’s software that makes that sketchy. MeerK40t uses it to do pixel perfect curves around corners. Some older versions of Whisperer before I fixed the speed codes (I wrote the speed code for Whisperer nothing else, I write MeerK40t) may have done the corners in a non-optimal fashion.

You can show that standard PPI power modulation would do the same thing as dither engraving. But, also, you can easily go back over the original image with different speeds to get different depths. The utility of PWM power modulation is not that great.

The board runs like $20 for like $10 of hardware. CH341 chip, 8051 microprocessor, two fairly cheap stepper chips. And it’s not actually outdated technology. It’s gets better rastering speeds than many GRBL devices.

The code is fairly well documented by me.

https://github.com/meerk40t/meerk40t/wiki/Lhymicro-GL

It is not actually a form of g-code. That’s an error. It’s actually specially designed code to work with the lasercutter. It doesn’t contain anything more than commands that flip modes on the chip. So the speed codes set the PWM tick rate, the R, L, T, B commands set the direction on the chip. The a-z distance commands simply append distance to a tick bucket. It not derived or derivative of GCode. It’s actually a pretty interesting technology in itself.

The results are that it can raster faster than a lot of GRBL boards on a 40 year old processor (the Intel 8051 was developed in 1980). Because lhymicro-gl basically just a microcontroller dataset. Commands like draw a line or curve or modulate something are not included. Those commands require a processor that does processing, the board itself just flips the switches it has, like the direction switch on the stepper motor chip, or hooks the stepper pulse to a particular timer.

We would actually do well to stop running lasercutters with CNC code that needs to calculate a bunch of stuff to perform arc commands etc.

Hi

I just got the MiniGerbil and Lightburn. I have the digital K40, and my question is:

When I set the power at 45% on the digital my AM read out 15mA on the testbutton, but when the maschine is cutting, the AM read only 4-5 mA. And the cutting is almost nonexisting!

Even when setting in Lightburn is 100%.

Must the powersetting be 100% on the digital?

Hans

Hi Hans,

when Mini Gerbil is installed, Lightburn completely controls the laser power. The digital panel control and display are not used.

If you have trouble cutting then check your wiring installation, and the settings in Lightburn. You can provide more details (all your Lightburn settings and a photo of your installation) in a K40 forum question and we can help you sort it out.

Regards,

Dan

Hi Dan

I was told, that the digital still works as a pot meter, and that Lightburn uses that output as Maximus.

Hans

This is caused by a mistake. Wrong wiring. Foolish.

Mine works the same

When i set digital to 0, lightburn will testfire but not engrave

When i set it to 50, it works.

How can i fix that wiring?