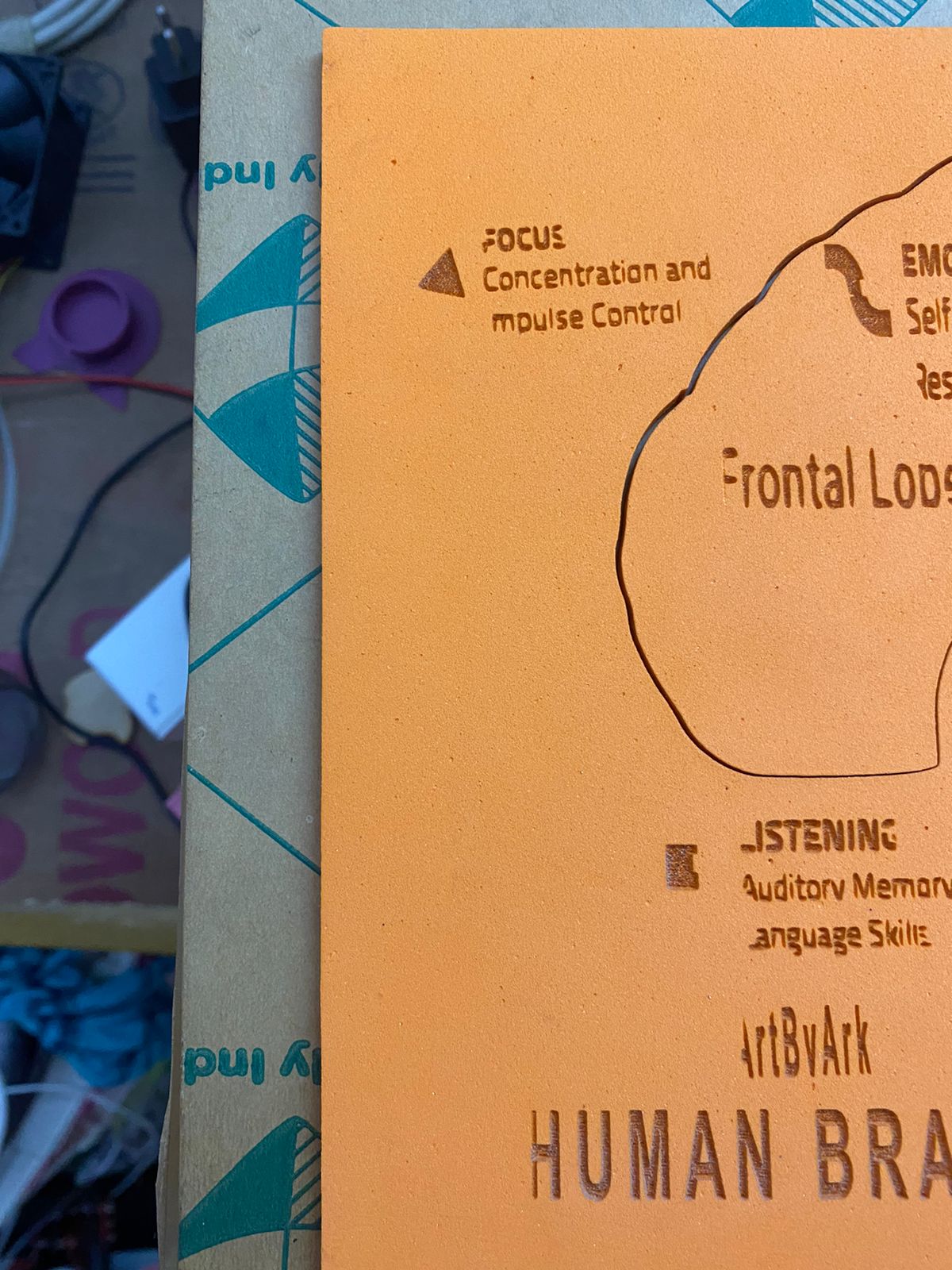

Overlapping shapes and text

Quote from Jayan Bala on November 1, 2022, 3:28 pmAll the below issue are not there if i replace the old Mosi board which came with the laser , so obstacle , or belt issue .

I used the same light burn to cut the below objects on my Ortur laster master it is totaly fine.

New MG3 board on a 60w chinese Laser, trial version of latest version of Light burn.

Waiting for connection...

Waiting for connection...

Grbl 1.1f ['$' for help]

ok

ok

[VER:1.1f.20211209:]

[OEM:Awesome.tech . MiniGerbil_MG3:]

[SER:MG3_0003.Date:2021209:]

[OPT:VMZL,15,250]

Target buffer size found

ok

$0=10

$1=25

$2=0

$3=2

$4=1

$5=1

$6=0

$10=1

$11=0.010

$12=0.002

$13=0

$20=0

$21=1

$22=1

$23=3

$24=20.000

$25=40.000

$26=126

$27=4.000

$28=5

(Pwm freq 0-15)

$30=1000

$31=1

$32=1

$94=0

$95=0

$96=1

$97=0

$98=1

$99=1

$100=157.000

(x:stp/mm)

$101=157.000

(y:stp/mm)

$102=160.000

(z:stp/mm)

$110=12000.000

(x:mm/min)

$111=5000.000

(y:mm/min)

$112=5000.000

(z:mm/min)

$120=1600.000

(x:mm/s^2)

$121=1200.000

(y:mm/s^2)

$122=3000.000

(z:mm/s^2)

$130=320.000

(x:mm max)

$131=230.000

(y:mm max)

$132=200.000

(z:mm max)

ok

$$

$0=10

$1=25

$2=0

$3=2

$4=1

$5=1

$6=0

$10=1

$11=0.010

$12=0.002

$13=0

$20=0

$21=1

$22=1

$23=3

$24=20.000

$25=40.000

$26=126

$27=4.000

$28=5

(Pwm freq 0-15)

$30=1000

$31=1

$32=1

$94=0

$95=0

$96=1

$97=0

$98=1

$99=1

$100=157.000

(x:stp/mm)

$101=157.000

(y:stp/mm)

$102=160.000

(z:stp/mm)

$110=12000.000

(x:mm/min)

$111=5000.000

(y:mm/min)

$112=5000.000

(z:mm/min)

$120=1600.000

(x:mm/s^2)

$121=1200.000

(y:mm/s^2)

$122=3000.000

(z:mm/s^2)

$130=320.000

(x:mm max)

$131=230.000

(y:mm max)

$132=200.000

(z:mm max)

ok

Its kinda had to say the issue as there are multiple issues.

- The homing does not work , and makes grinding noise .

- Characters are shrunk.

- few are overlapping though i have set to 500mm x 500mm as per my cut area

- few cuts in a zig zag pattern one above , one below other time , one on left top or bottom and the other right top or bottom

- Whining noise or grinding noise when moving to a point , which was not the case with the other board.

Had to either stop the homing manually and start the test cut of circles or stop the home on start up.

All the below issue are not there if i replace the old Mosi board which came with the laser , so obstacle , or belt issue .

I used the same light burn to cut the below objects on my Ortur laster master it is totaly fine.

New MG3 board on a 60w chinese Laser, trial version of latest version of Light burn.

Waiting for connection...

Waiting for connection...

Grbl 1.1f ['$' for help]

ok

ok

[VER:1.1f.20211209:]

[OEM:Awesome.tech . MiniGerbil_MG3:]

[SER:MG3_0003.Date:2021209:]

[OPT:VMZL,15,250]

Target buffer size found

ok

$0=10

$1=25

$2=0

$3=2

$4=1

$5=1

$6=0

$10=1

$11=0.010

$12=0.002

$13=0

$20=0

$21=1

$22=1

$23=3

$24=20.000

$25=40.000

$26=126

$27=4.000

$28=5

(Pwm freq 0-15)

$30=1000

$31=1

$32=1

$94=0

$95=0

$96=1

$97=0

$98=1

$99=1

$100=157.000

(x:stp/mm)

$101=157.000

(y:stp/mm)

$102=160.000

(z:stp/mm)

$110=12000.000

(x:mm/min)

$111=5000.000

(y:mm/min)

$112=5000.000

(z:mm/min)

$120=1600.000

(x:mm/s^2)

$121=1200.000

(y:mm/s^2)

$122=3000.000

(z:mm/s^2)

$130=320.000

(x:mm max)

$131=230.000

(y:mm max)

$132=200.000

(z:mm max)

ok

$$

$0=10

$1=25

$2=0

$3=2

$4=1

$5=1

$6=0

$10=1

$11=0.010

$12=0.002

$13=0

$20=0

$21=1

$22=1

$23=3

$24=20.000

$25=40.000

$26=126

$27=4.000

$28=5

(Pwm freq 0-15)

$30=1000

$31=1

$32=1

$94=0

$95=0

$96=1

$97=0

$98=1

$99=1

$100=157.000

(x:stp/mm)

$101=157.000

(y:stp/mm)

$102=160.000

(z:stp/mm)

$110=12000.000

(x:mm/min)

$111=5000.000

(y:mm/min)

$112=5000.000

(z:mm/min)

$120=1600.000

(x:mm/s^2)

$121=1200.000

(y:mm/s^2)

$122=3000.000

(z:mm/s^2)

$130=320.000

(x:mm max)

$131=230.000

(y:mm max)

$132=200.000

(z:mm max)

ok

Its kinda had to say the issue as there are multiple issues.

- The homing does not work , and makes grinding noise .

- Characters are shrunk.

- few are overlapping though i have set to 500mm x 500mm as per my cut area

- few cuts in a zig zag pattern one above , one below other time , one on left top or bottom and the other right top or bottom

- Whining noise or grinding noise when moving to a point , which was not the case with the other board.

Had to either stop the homing manually and start the test cut of circles or stop the home on start up.

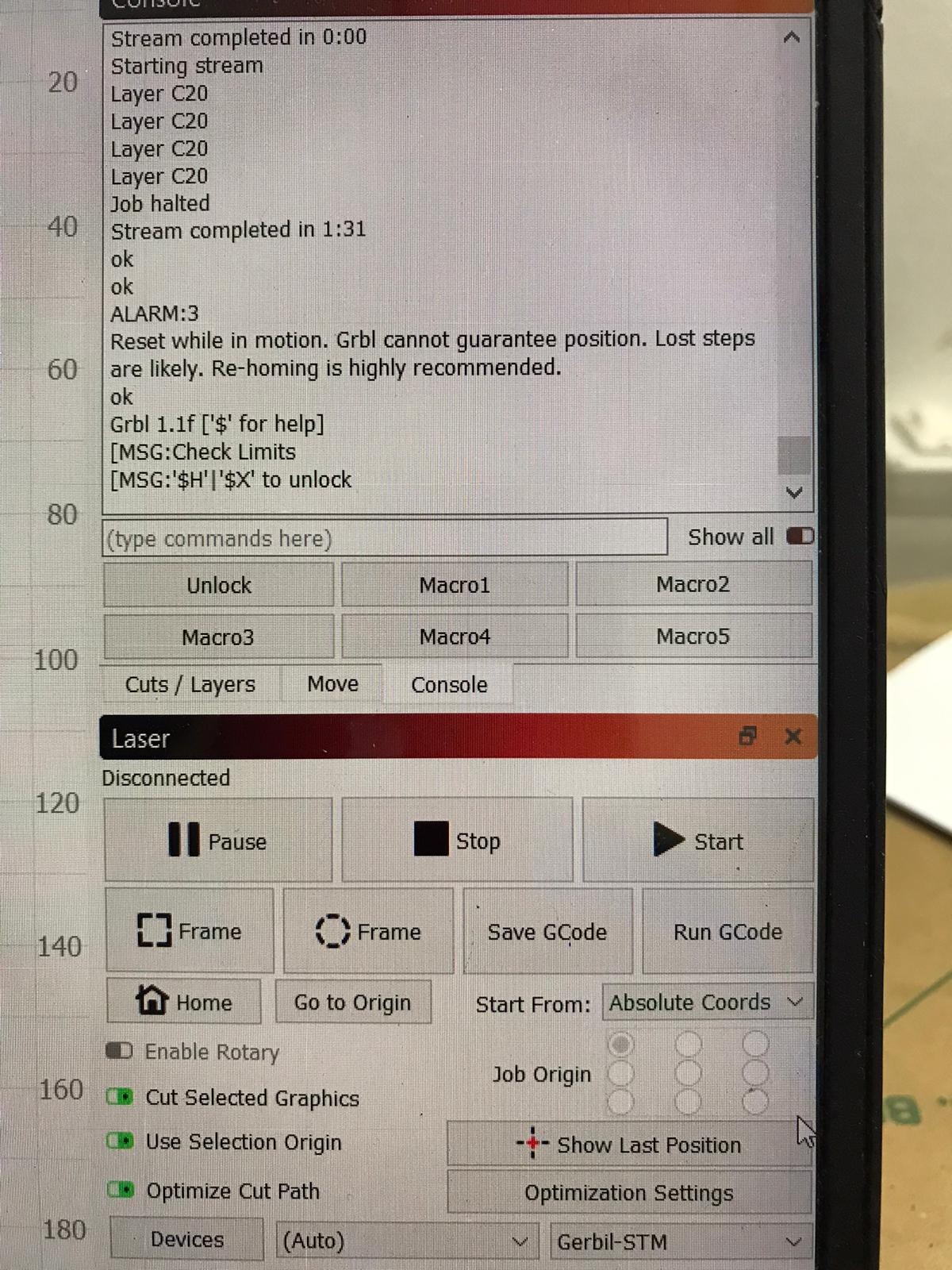

Quote from dancolwp1974 on November 1, 2022, 8:55 pmHi Jayan,

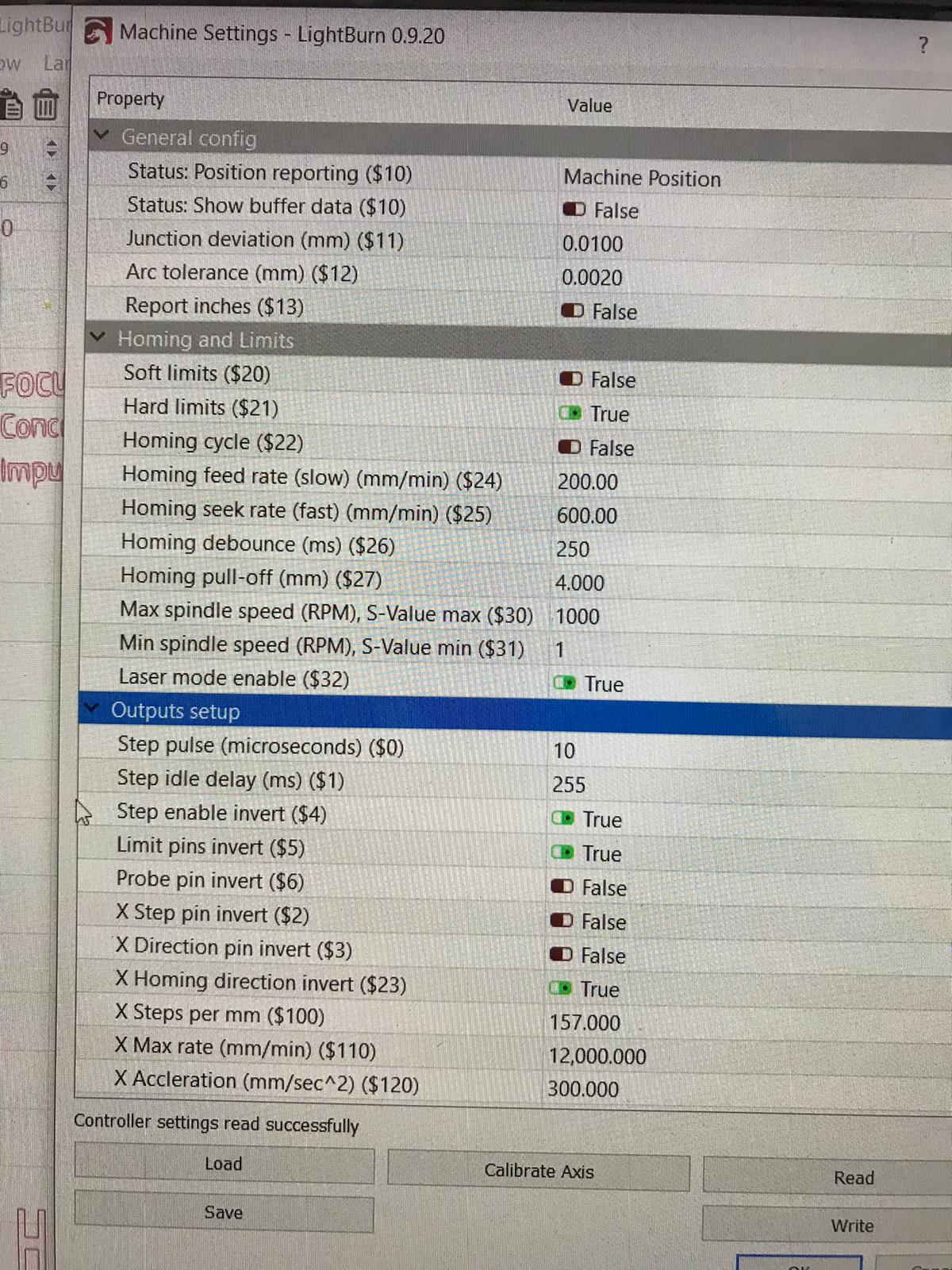

I spotted a big problem with your $ values!!

Your list shows $1=25

The correct value is $1=255

We developed the correct values after a lot of experimentation and optimisation, so big changes like this will cause severe problems. Could you please reset by typing $1=255 in the console

Your machine should work as normal then.

Regards,

Dan

Hi Jayan,

I spotted a big problem with your $ values!!

Your list shows $1=25

The correct value is $1=255

We developed the correct values after a lot of experimentation and optimisation, so big changes like this will cause severe problems. Could you please reset by typing $1=255 in the console

Your machine should work as normal then.

Regards,

Dan

Quote from Jayan Bala on November 1, 2022, 10:59 pmWe made few changes and the $1 was one among them which resulted in 90% ok of cut and engraving.

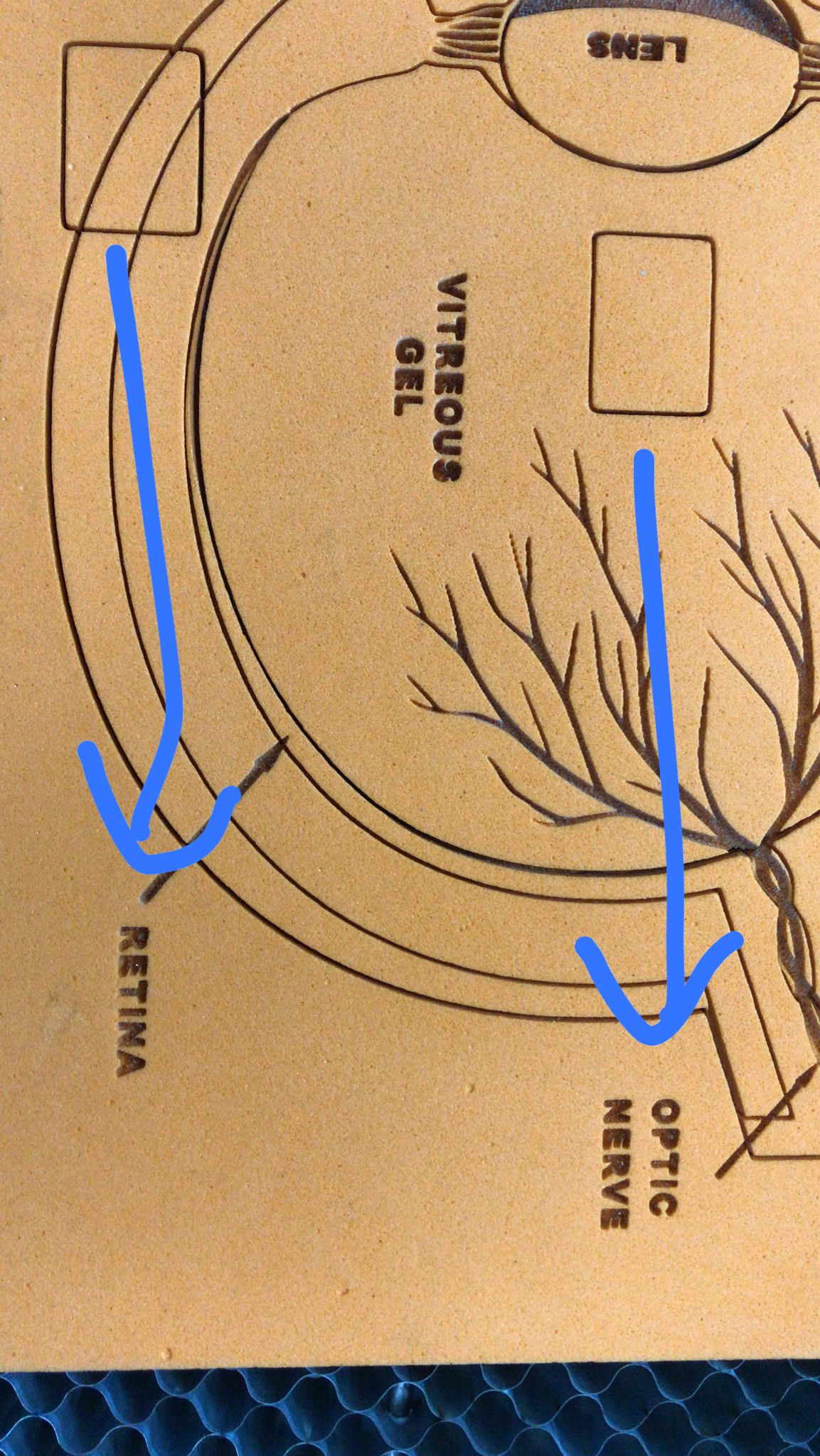

We have set the $1=255 as per you suggestion and here is the output where in we can see the first characters are not complete .

We made few changes and the $1 was one among them which resulted in 90% ok of cut and engraving.

We have set the $1=255 as per you suggestion and here is the output where in we can see the first characters are not complete .

Uploaded files:

Quote from dancolwp1974 on November 1, 2022, 11:05 pmThis is a fascinating problem, I understand the laser is scanning vertically (relative to the image shown), and the first column or two isn't operating right? So this is a case of the movement is working right, but the laser isn't warm enough to operate initially. Is your power supply or laser tube old? Have you tried increasing your laser power level, you might be operating close to the laser threshold. Lightburn also has some more advanced threshhold settings to learn.

So I imagine that if you do a small shape and then some text in the same job, the small shape won't appear, but the text would?

This is a fascinating problem, I understand the laser is scanning vertically (relative to the image shown), and the first column or two isn't operating right? So this is a case of the movement is working right, but the laser isn't warm enough to operate initially. Is your power supply or laser tube old? Have you tried increasing your laser power level, you might be operating close to the laser threshold. Lightburn also has some more advanced threshhold settings to learn.

So I imagine that if you do a small shape and then some text in the same job, the small shape won't appear, but the text would?

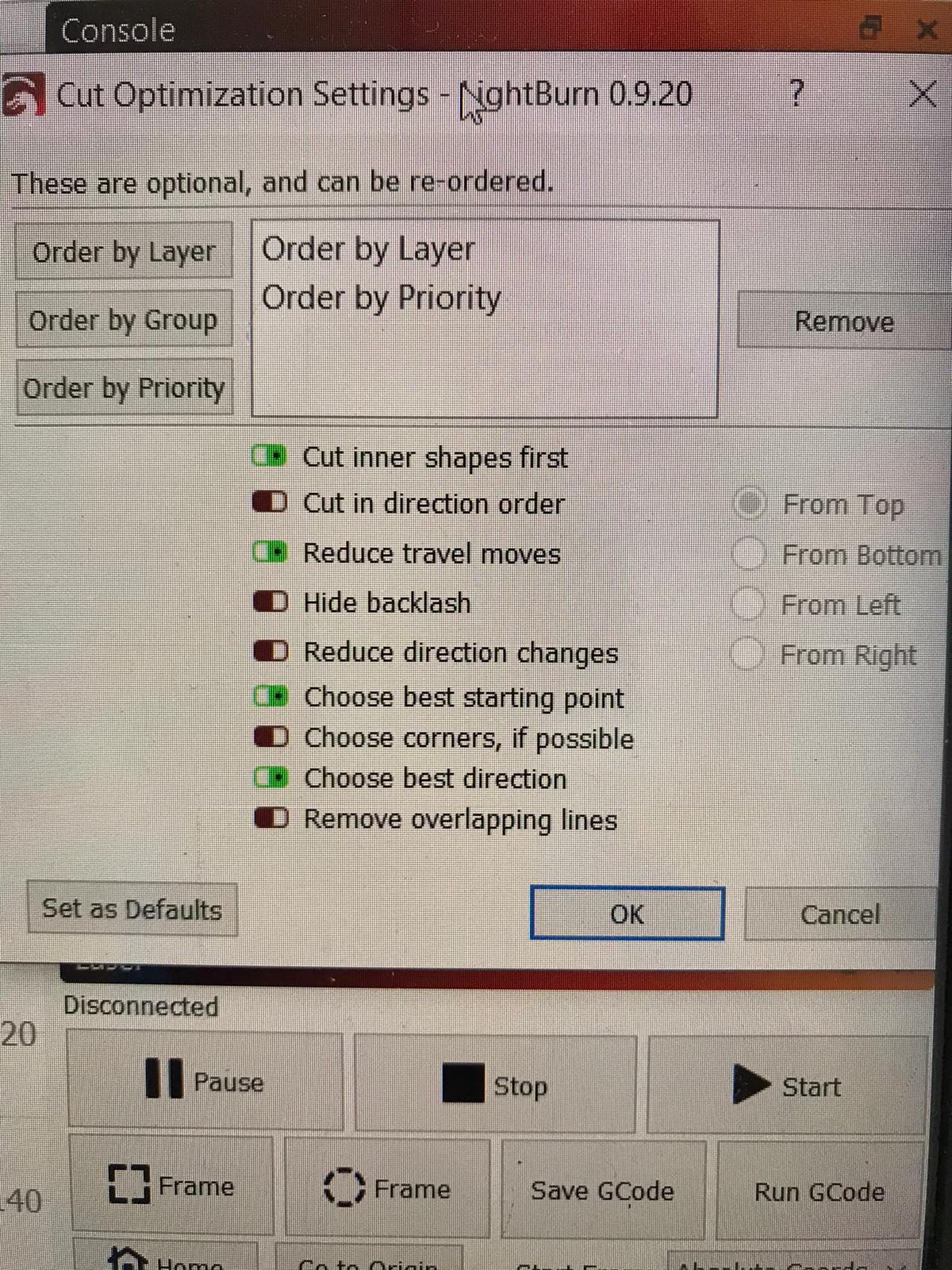

Quote from Jayan Bala on November 2, 2022, 2:49 amHello Dan,

Thank you for your quick reply.

The Engraving is set to layer order , we even tried individual and priority as well all end up with the first characters line the same way , if you notice the top part (5th layer) of the character also has the issue , this is not heating issue i guess.

Laser is almost brand new and as stated in the first line , none of these issues are there if i replace back to moshi board.

Laser power for X and Y has been increased.

If i cut a small object as the first thing once i start the laser , it is able to cut clean now but i noticed this on the characters as of now.

Also i still have the homing grinding issue ( again not present on old board if i change it), currently am operating with homing turned off and using $X for every stop and using absolute coordinates.

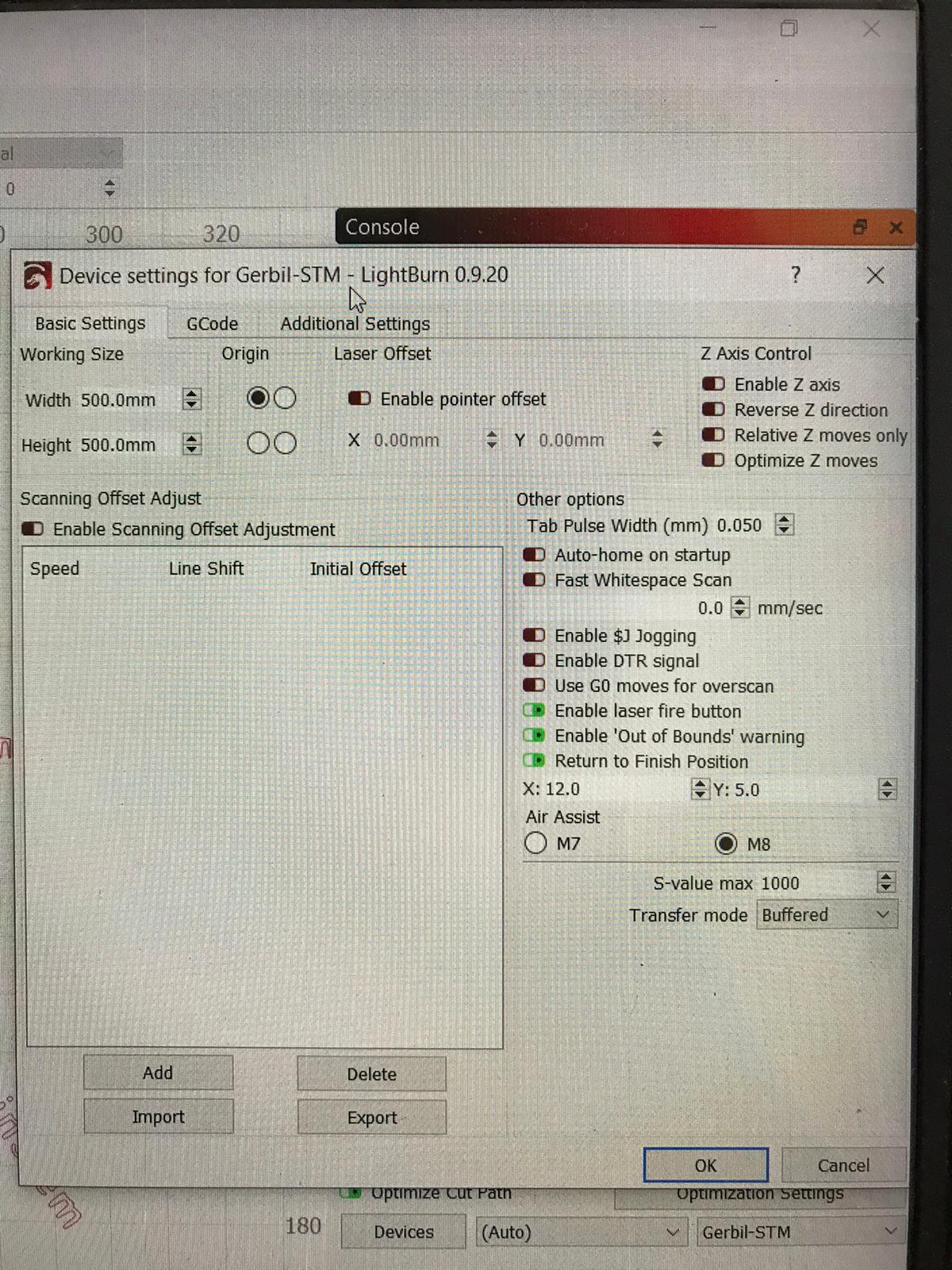

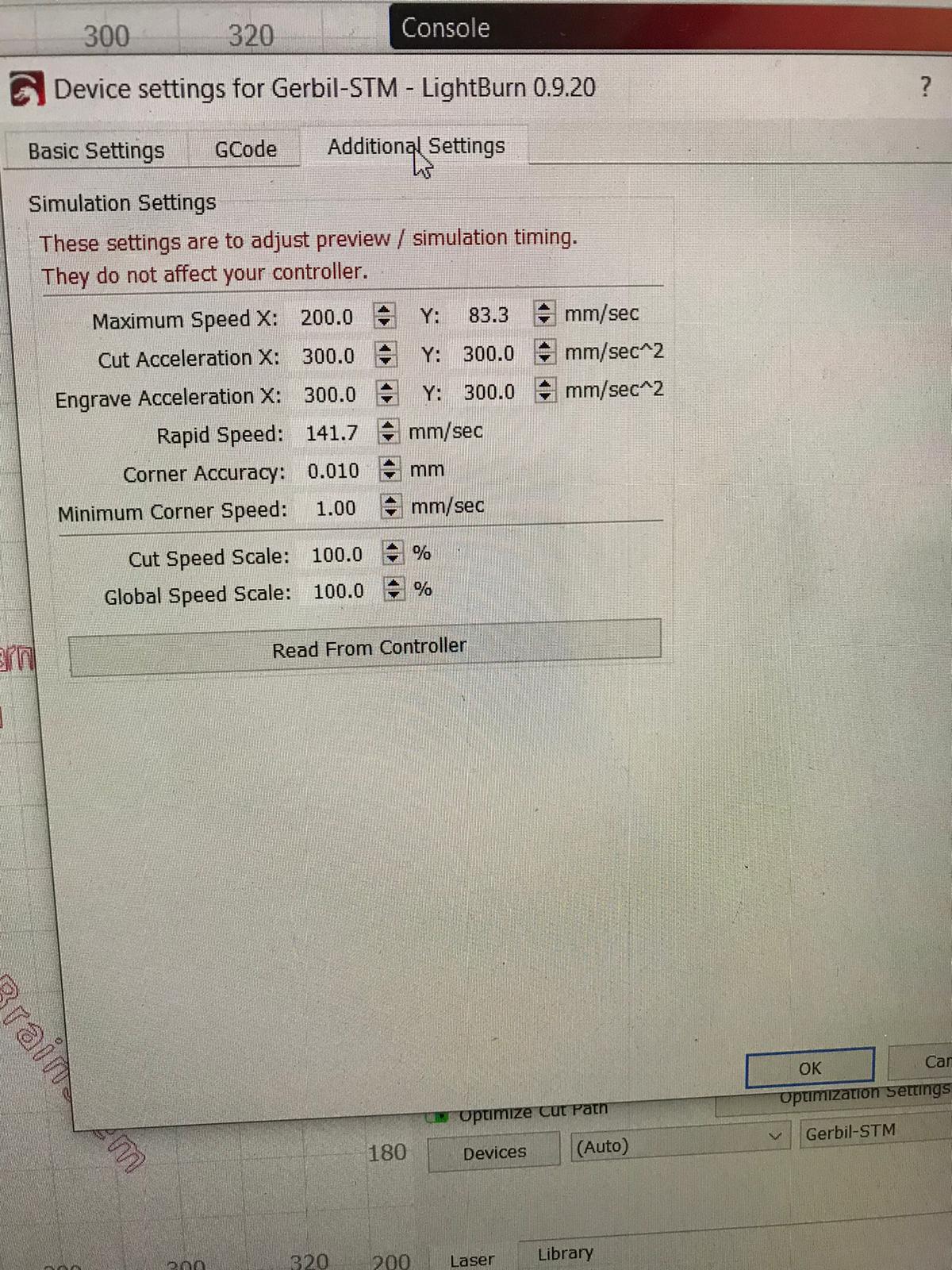

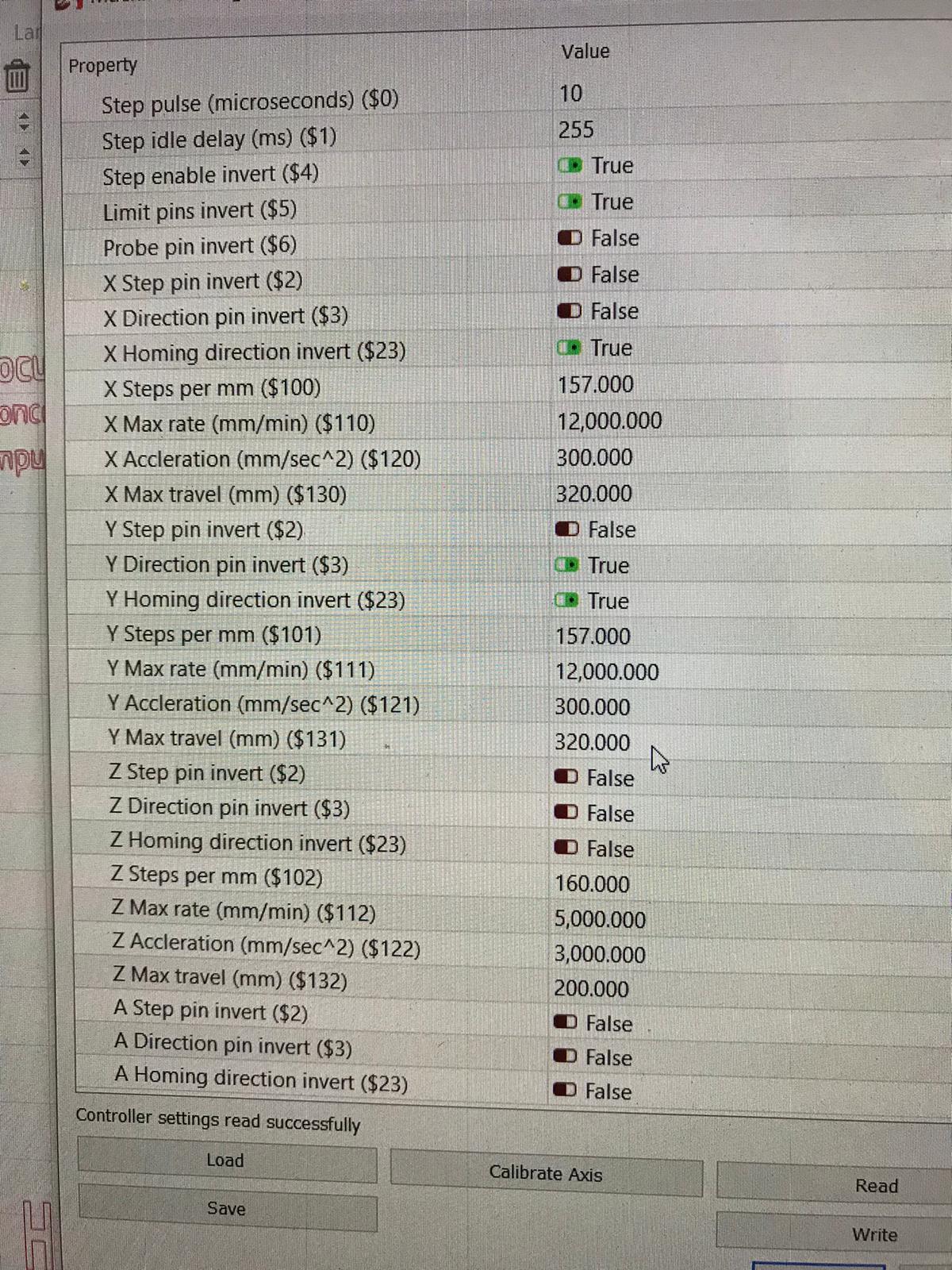

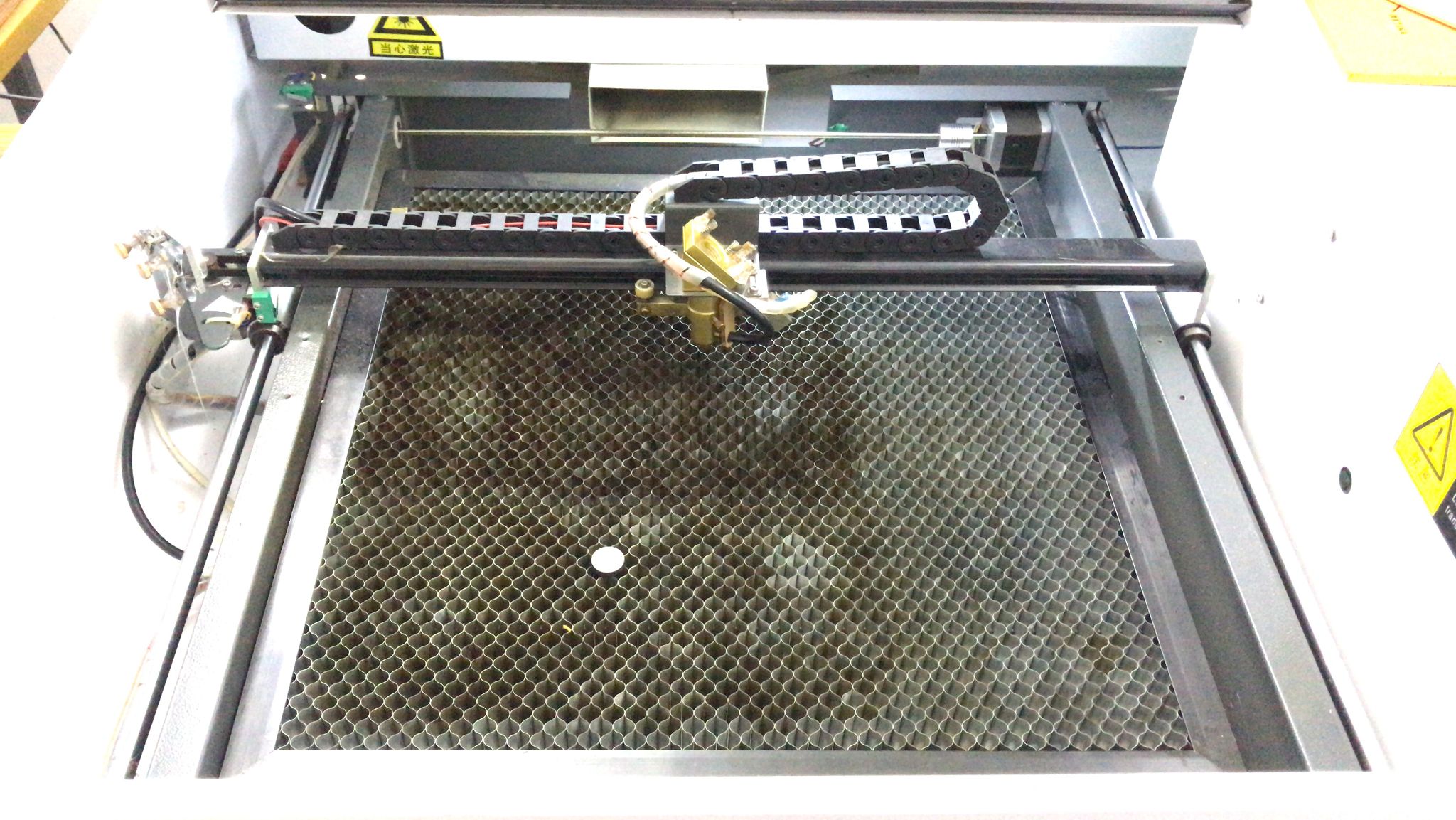

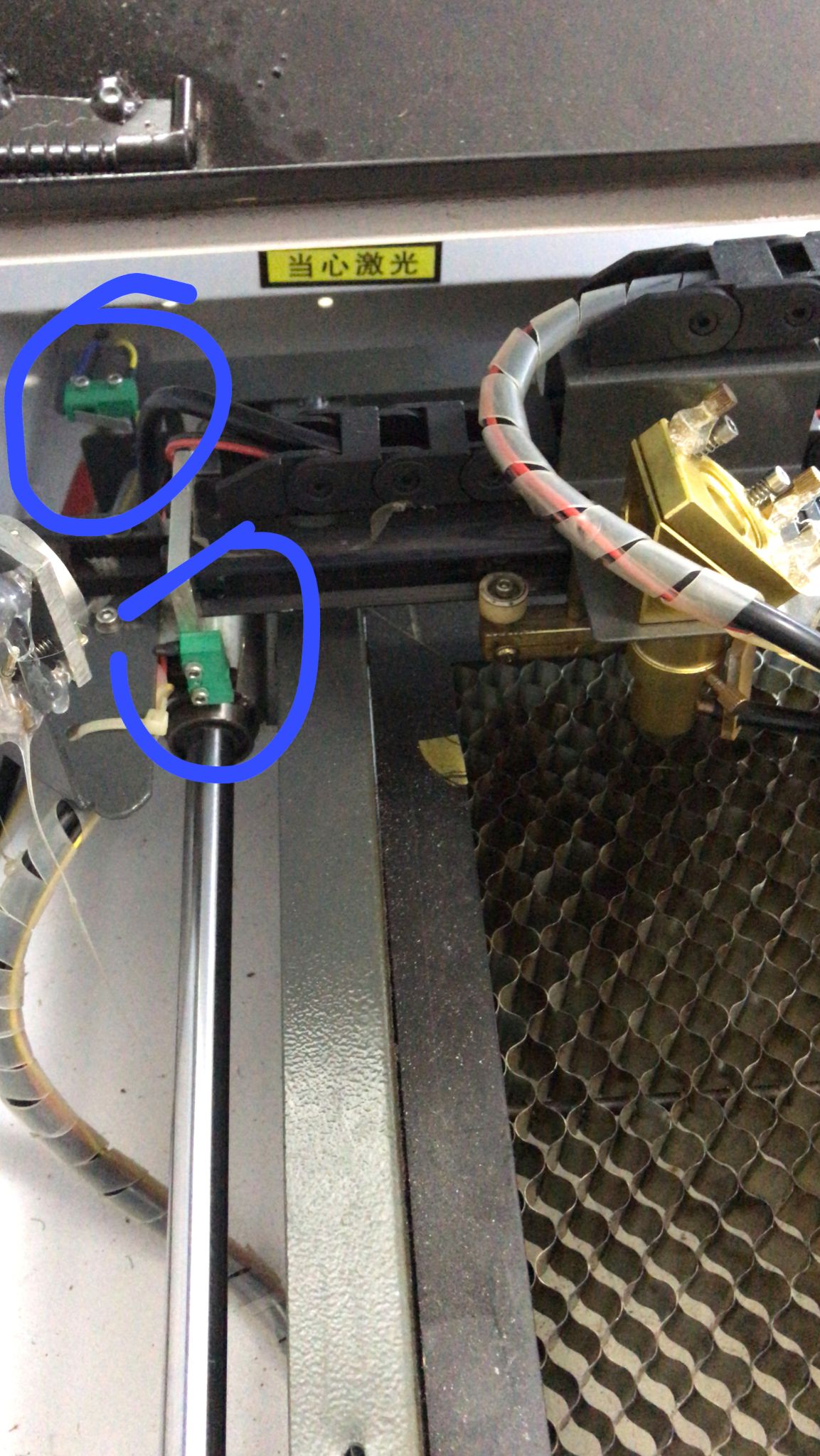

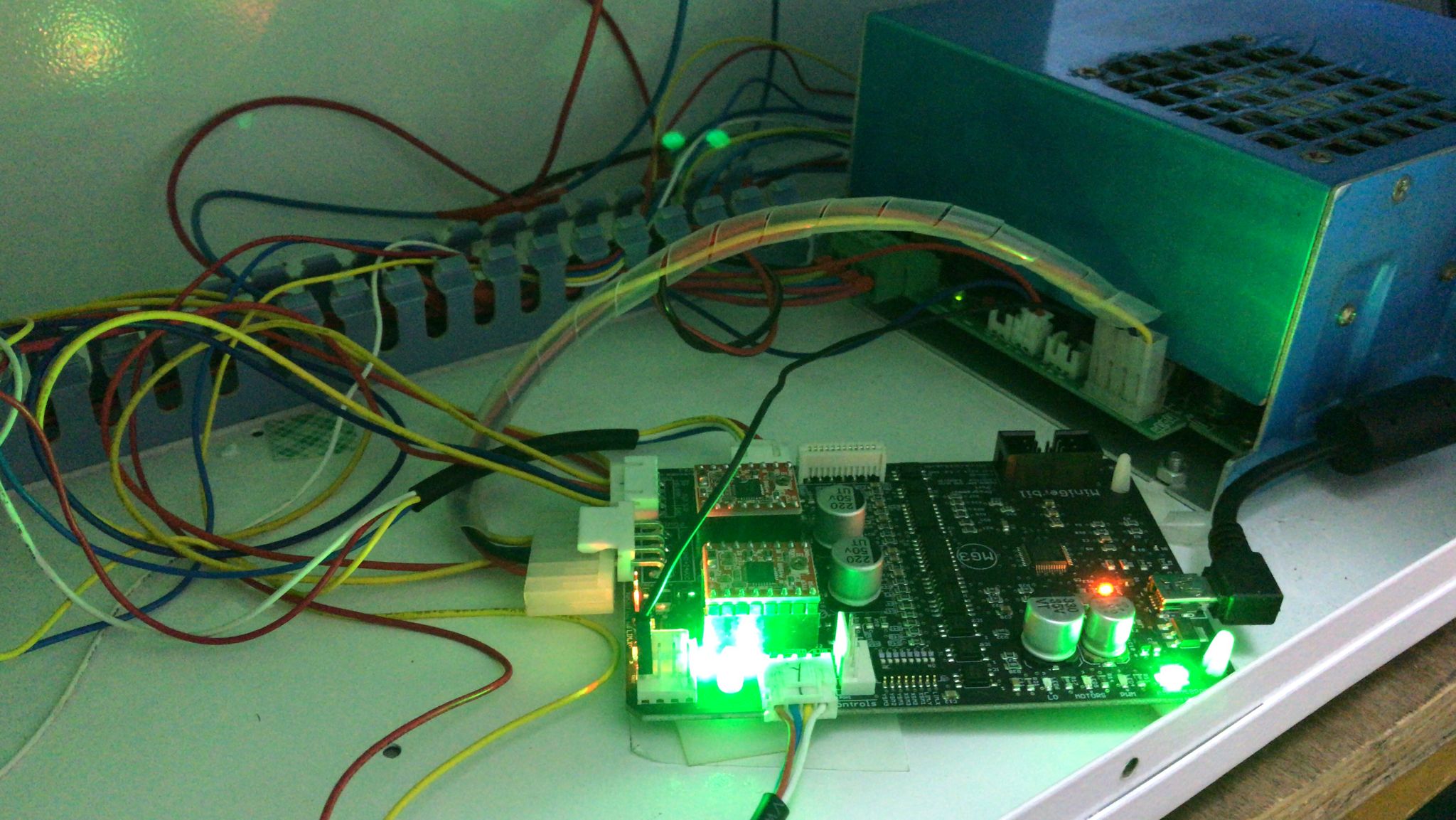

Am attaching my settings and well as my machine pics to show i have set to top left where there is X and Y limit switch and there are no obstructions.

The last picture if you notices almost everything came us as expected but at the end the boxes where supposed to be on the right but ended up in middle at the end when completing the cut 🙁

Hello Dan,

Thank you for your quick reply.

The Engraving is set to layer order , we even tried individual and priority as well all end up with the first characters line the same way , if you notice the top part (5th layer) of the character also has the issue , this is not heating issue i guess.

Laser is almost brand new and as stated in the first line , none of these issues are there if i replace back to moshi board.

Laser power for X and Y has been increased.

If i cut a small object as the first thing once i start the laser , it is able to cut clean now but i noticed this on the characters as of now.

Also i still have the homing grinding issue ( again not present on old board if i change it), currently am operating with homing turned off and using $X for every stop and using absolute coordinates.

Am attaching my settings and well as my machine pics to show i have set to top left where there is X and Y limit switch and there are no obstructions.

The last picture if you notices almost everything came us as expected but at the end the boxes where supposed to be on the right but ended up in middle at the end when completing the cut 🙁

Uploaded files:

Quote from dancolwp1974 on November 3, 2022, 9:07 pmHi Jayan,

Laser slow to turn on (first scan lines missing)

Ok I have some new information, pretty sure this should fix things.

The thing about laser machines is that they can be purchased new, but the laser tubes within them may have been sitting in the warehouse for a while. (With the power off) take a look at your tube, you may see a sticker with manufacturing date on it. The gases in the laser tube slowly leak out through the 'solid' glass, independent of whether it is sitting unused, or being operated as a laser. The changing gas composition changes the characteristics of the tube, and may require more electrical current to force the tube into lasering.

The good news? The above phenomenon is well known enough that a fix has been designed into the $ settings used in GRBL, which the MG3 uses. The amount of electrical current fed to the laser tube so that it will instantly turn on when the full current is supplied, is called the 'tickle current'. So it's a level of current that doesn't cause lasering, but it's very close to it, such that a small increase in current will quickly cause full lasering. $31 is the setting which specifies the tickle current.

So try gradually increasing the tickle current until the first scan line of your image appears correct. If you set the tickle current too low, you will still miss part of your first line. If you set it too high, the tube will be continuously firing before it is supposed to.

Grinding issue

Can you advise exactly when the grinding is occurring?

- If it is occurring only at homing operation, then please follow these steps and reply back with the scenario number. https://awesome.tech/2-part-home-at-power-up/ Another thing to try: review https://awesome.tech/limit-switches-and-homing/ and consider trying a small increase to the homing pull-off distance ($27) try setting it to 5mm, and if your limit switches are poor quality and bounce around, increase $26 as well

- If the grinding happens at other times, then it's a motor power issue. If you have already tried increasing stepstick current (like I previously advised) then you need to move to external stepper motor drivers for your gantry size and build quality. Before going to the trouble of this, you may like to verify the limited motor power by lightening the load of your gantry. While the air hose doesn't way much, it does provide an elastic force for the motors to overcome. Your laser head (ie. Final mirror assembly) looks relatively bulky, and if you temporarily lighten it and get reduced grinding, then it all just points to the fact that your motors need more power to work reliably.

General gremlins

Please action the following https://awesome.tech/k40-laser-grounding-instructions/

Thanks

Dan

Hi Jayan,

Laser slow to turn on (first scan lines missing)

Ok I have some new information, pretty sure this should fix things.

The thing about laser machines is that they can be purchased new, but the laser tubes within them may have been sitting in the warehouse for a while. (With the power off) take a look at your tube, you may see a sticker with manufacturing date on it. The gases in the laser tube slowly leak out through the 'solid' glass, independent of whether it is sitting unused, or being operated as a laser. The changing gas composition changes the characteristics of the tube, and may require more electrical current to force the tube into lasering.

The good news? The above phenomenon is well known enough that a fix has been designed into the $ settings used in GRBL, which the MG3 uses. The amount of electrical current fed to the laser tube so that it will instantly turn on when the full current is supplied, is called the 'tickle current'. So it's a level of current that doesn't cause lasering, but it's very close to it, such that a small increase in current will quickly cause full lasering. $31 is the setting which specifies the tickle current.

So try gradually increasing the tickle current until the first scan line of your image appears correct. If you set the tickle current too low, you will still miss part of your first line. If you set it too high, the tube will be continuously firing before it is supposed to.

Grinding issue

Can you advise exactly when the grinding is occurring?

- If it is occurring only at homing operation, then please follow these steps and reply back with the scenario number. https://awesome.tech/2-part-home-at-power-up/ Another thing to try: review https://awesome.tech/limit-switches-and-homing/ and consider trying a small increase to the homing pull-off distance ($27) try setting it to 5mm, and if your limit switches are poor quality and bounce around, increase $26 as well

- If the grinding happens at other times, then it's a motor power issue. If you have already tried increasing stepstick current (like I previously advised) then you need to move to external stepper motor drivers for your gantry size and build quality. Before going to the trouble of this, you may like to verify the limited motor power by lightening the load of your gantry. While the air hose doesn't way much, it does provide an elastic force for the motors to overcome. Your laser head (ie. Final mirror assembly) looks relatively bulky, and if you temporarily lighten it and get reduced grinding, then it all just points to the fact that your motors need more power to work reliably.

General gremlins

Please action the following https://awesome.tech/k40-laser-grounding-instructions/

Thanks

Dan

Quote from Jayan Bala on November 5, 2022, 4:07 pmGrinding issue

Can you advise exactly when the grinding is occurring?

The Grinding is always when homing but does not come when we have the moshi board , the grinding comes when stating the job and the head tries to reach the start area .

I have tried increasing the homing , no good.

Also i have increased the stepstick starting with 15 turn to all the way i so no power increase however i see text are jumbled after that.

Anyway i am forced to giveup as production is impacted and gone for moshi board and all are fine as before .

I will try to resume after couple of months once we have stocks of product.

Thank you Dan, you have been a great support and help.

I wish i had you over call to fix the same in few mins rather than days 🙂

Thank you once again Dan 🙂

Grinding issue

Can you advise exactly when the grinding is occurring?

The Grinding is always when homing but does not come when we have the moshi board , the grinding comes when stating the job and the head tries to reach the start area .

I have tried increasing the homing , no good.

Also i have increased the stepstick starting with 15 turn to all the way i so no power increase however i see text are jumbled after that.

Anyway i am forced to giveup as production is impacted and gone for moshi board and all are fine as before .

I will try to resume after couple of months once we have stocks of product.

Thank you Dan, you have been a great support and help.

I wish i had you over call to fix the same in few mins rather than days 🙂

Thank you once again Dan 🙂

Quote from dancolwp1974 on November 5, 2022, 4:34 pmYou're welcome. It is tricky to provide remote support for electromechanical devices.

For me to help you further, remember you must advise on the exact scenario number you experience from this link

https://awesome.tech/2-part-home-at-power-up/

Regards,

Dan

You're welcome. It is tricky to provide remote support for electromechanical devices.

For me to help you further, remember you must advise on the exact scenario number you experience from this link

https://awesome.tech/2-part-home-at-power-up/

Regards,

Dan