Power increase after engraving for a while.

Quote from Roberth8 on September 14, 2019, 8:01 amHi Paul.

All in all the Mini Gerbil is performing well on my K40.

However, after about 10-20 minutes of using the laser all of a sudden there is a consistent increase in the laser power output. It about doubles for no reason that is apparent and stays there until the next time I use the system from cold and dark.

Once that power increase has kicked in it runs evenly. It is like it is taking to time to 'heat up' or something. I have done a thorough 'microscopic' check of the wiring and every possible connection especially on the tube connections themselves. All is ok.Any thoughts on where else to look?

Also, I know I can wire the setup to use the k40 potentiometer for power levels but it requires the M4(?) command to fire and the Lightburn GCode doesn't seem to have a 'switch' to change from S.. power levels to straight M4 (off/on) for non-grayscale engraving.

Is it possible to have the pot inline to tweak the power output live, as I really need power adjustment 'on the fly' and prefer not to use CNCJS.thanks agin for all your help.

Hi Paul.

All in all the Mini Gerbil is performing well on my K40.

However, after about 10-20 minutes of using the laser all of a sudden there is a consistent increase in the laser power output. It about doubles for no reason that is apparent and stays there until the next time I use the system from cold and dark.

Once that power increase has kicked in it runs evenly. It is like it is taking to time to 'heat up' or something. I have done a thorough 'microscopic' check of the wiring and every possible connection especially on the tube connections themselves. All is ok.

Any thoughts on where else to look?

Also, I know I can wire the setup to use the k40 potentiometer for power levels but it requires the M4(?) command to fire and the Lightburn GCode doesn't seem to have a 'switch' to change from S.. power levels to straight M4 (off/on) for non-grayscale engraving.

Is it possible to have the pot inline to tweak the power output live, as I really need power adjustment 'on the fly' and prefer not to use CNCJS.

thanks agin for all your help.

Quote from Paul on September 14, 2019, 9:28 amIt's likely that there is a bad connection of the High Voltage connection to the tube. Once the tube warms up, the connection lead loosens or crimps. So you need to re-attach it or else it could be a Power supply issue. (hard to test though)

You can set the max S level in lightburn and in the MG ($30 value). Issue a $30=2000 which set the range from 1000 S points to 2000. Experiment a bit with the Lightburn S settings as well. You could leave the $30=1000 but increase/decrease just the S parm in Lightburn. Let me know if this worked for you

It's likely that there is a bad connection of the High Voltage connection to the tube. Once the tube warms up, the connection lead loosens or crimps. So you need to re-attach it or else it could be a Power supply issue. (hard to test though)

You can set the max S level in lightburn and in the MG ($30 value). Issue a $30=2000 which set the range from 1000 S points to 2000. Experiment a bit with the Lightburn S settings as well. You could leave the $30=1000 but increase/decrease just the S parm in Lightburn. Let me know if this worked for you

Uploaded files:

Quote from Roberth8 on September 18, 2019, 8:05 amThanks gain for your help Paul.

I checked and rechecked the connections in the PSU and to the tube and everything is solid.

I worked (actually for hours....I really need to get a life) trying different LB settings and tried working with CNCJS to find something that had an impact on it to no avail.

I think the PSU is hosed but I don't know for sure.

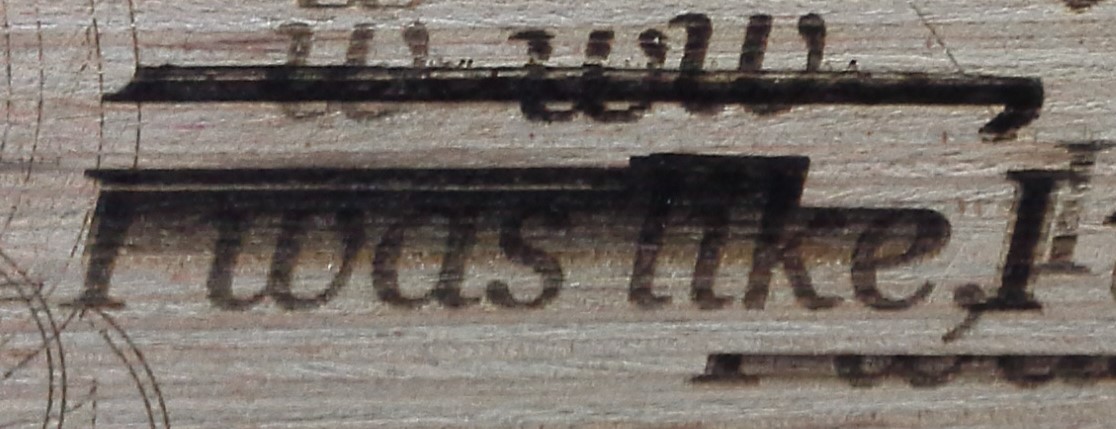

Here is a pic of what is happening. The burn is from the bottom up:Is there any possibility I could have a bad MiniGerbil board although I highly doubt that.

Anyways, do have any idea where I could get a new PSU at a decent price? (The disability pension doesn't go very far these days.)

Thanks gain for your help Paul.

I checked and rechecked the connections in the PSU and to the tube and everything is solid.

I worked (actually for hours....I really need to get a life) trying different LB settings and tried working with CNCJS to find something that had an impact on it to no avail.

I think the PSU is hosed but I don't know for sure.

Here is a pic of what is happening. The burn is from the bottom up:

Is there any possibility I could have a bad MiniGerbil board although I highly doubt that.

Anyways, do have any idea where I could get a new PSU at a decent price? (The disability pension doesn't go very far these days.)

Uploaded files:

Quote from Paul on September 18, 2019, 2:16 pmHi, that's a very new symptom I have not seen before. You could hook up a 5k pot on the 5v, IN, Gnd pins where the middle of the pot is attached to IN.

Run an engraving without the MG PWM attached to IN, so only the pot. See if this happens again, if it does then it's the PSU otherwise the MG might be the cause. Let me know what you find.

cheers, Paul

Hi, that's a very new symptom I have not seen before. You could hook up a 5k pot on the 5v, IN, Gnd pins where the middle of the pot is attached to IN.

Run an engraving without the MG PWM attached to IN, so only the pot. See if this happens again, if it does then it's the PSU otherwise the MG might be the cause. Let me know what you find.

cheers, Paul

Quote from Roberth8 on December 6, 2019, 7:01 amWell I finally got my pot from China and installed it as you said, middle pot pin to IN.

The laser fired but only at full level and adjusting the pot made no difference.I tried a line drawing using LB and it works fine attaching the original K40 Pot from the panel to all three pins.

So, I guess I am stumped. Not sure how to proceed. It appears the PSU is fine based on the results of using the original panel pot.

Should I try a replacement MG board?

Well I finally got my pot from China and installed it as you said, middle pot pin to IN.

The laser fired but only at full level and adjusting the pot made no difference.

I tried a line drawing using LB and it works fine attaching the original K40 Pot from the panel to all three pins.

So, I guess I am stumped. Not sure how to proceed. It appears the PSU is fine based on the results of using the original panel pot.

Should I try a replacement MG board?

Quote from Paul on December 6, 2019, 10:02 amHi Robert, the replacement pot needs 5v DC, IN and GND. Not sure if you have wired the potmeter with three connections? Firing at full means the IN does not get any DC voltage level.

Please let me know how you have wired the pot or take a picture so I can help you a bit further.

Thanks, PAul

Hi Robert, the replacement pot needs 5v DC, IN and GND. Not sure if you have wired the potmeter with three connections? Firing at full means the IN does not get any DC voltage level.

Please let me know how you have wired the pot or take a picture so I can help you a bit further.

Thanks, PAul

Quote from Roberth8 on December 7, 2019, 3:31 amYup, that worked. Just connecting the GND pin did the trick and the pot attenuates the beam accordingly.

I burned several jobs and the level of intensity remained consistent.

Does that suggest a MG issue or something else?

Yup, that worked. Just connecting the GND pin did the trick and the pot attenuates the beam accordingly.

I burned several jobs and the level of intensity remained consistent.

Does that suggest a MG issue or something else?

Quote from Paul on December 17, 2019, 11:35 amYes you can post the image here. It's always nice for other users to see what is happening so they can learn from it. Thanks!

Yes you can post the image here. It's always nice for other users to see what is happening so they can learn from it. Thanks!

Quote from Roberth8 on December 25, 2019, 4:46 amWell, even with just setting the beam strength with the psu pot only arrangement, I am still getting job stalling and other issues so I think it is time to throw in the towel.

I don't know if it is the MG or my K40 but I have tried and done everything on this and the LB forum and it still just doesn't work. Must be why they charge so much for those other higher end units like Trotec.

I have been hemorrhaging time and cash for close to a year no with no luck.

Time to move on, Thanks for all your help.

Well, even with just setting the beam strength with the psu pot only arrangement, I am still getting job stalling and other issues so I think it is time to throw in the towel.

I don't know if it is the MG or my K40 but I have tried and done everything on this and the LB forum and it still just doesn't work. Must be why they charge so much for those other higher end units like Trotec.

I have been hemorrhaging time and cash for close to a year no with no luck.

Time to move on, Thanks for all your help.

Quote from Roberth8 on January 3, 2020, 8:58 amUpdate:

The little K40 has been working flawlessly with the pot wired in. It does suggest that the PSU is fine.

Still no joy when I wire the MG pwm to the IN on the PSU though.Is there a way for me to check with my voltmeter to ensure that the MG pwm signal is consistent?

Also, I don't know what the warranty is on the MG but would it be possible to get a replacement if there is a varying signal level problem?

Update:

The little K40 has been working flawlessly with the pot wired in. It does suggest that the PSU is fine.

Still no joy when I wire the MG pwm to the IN on the PSU though.

Is there a way for me to check with my voltmeter to ensure that the MG pwm signal is consistent?

Also, I don't know what the warranty is on the MG but would it be possible to get a replacement if there is a varying signal level problem?

Quote from HumptyDumpty on January 3, 2020, 3:54 pmIt might help to precisely describe what your problems are. And then take them on one at a time. Reading this thread looks to begin with you had some increased power issues, then with pot added you said it was working correctly. Then you said it was "stalling and other issues" ? It's difficult to help when the information provided is vague or contradictive.

At any rate to try to answer your last question you may be able to get a voltage reading off the PWM signal with a DMM but it's going to be an average voltage of the PWM signal. I believe when the IN pin is at 5V laser is off and at 0V laser is on at full power. So you should see something in between depending on what power your engraving at. If you engrave some some vertical bars all spaced evenly apart the voltage should read about the same throughout the scan. A scope would be the best way to see the signal coming off the PWM output though. I would suggest if your going to try to measure the voltages do it with a file similar to the attached image and DMM leads attached with jumper wires so your not poking around on the power supply while it's running.

It might help to precisely describe what your problems are. And then take them on one at a time. Reading this thread looks to begin with you had some increased power issues, then with pot added you said it was working correctly. Then you said it was "stalling and other issues" ? It's difficult to help when the information provided is vague or contradictive.

At any rate to try to answer your last question you may be able to get a voltage reading off the PWM signal with a DMM but it's going to be an average voltage of the PWM signal. I believe when the IN pin is at 5V laser is off and at 0V laser is on at full power. So you should see something in between depending on what power your engraving at. If you engrave some some vertical bars all spaced evenly apart the voltage should read about the same throughout the scan. A scope would be the best way to see the signal coming off the PWM output though. I would suggest if your going to try to measure the voltages do it with a file similar to the attached image and DMM leads attached with jumper wires so your not poking around on the power supply while it's running.

Uploaded files:Quote from Roberth8 on January 6, 2020, 5:17 amThanks for the instructions .

I have been debugging this for quite some time now and the other issues like stalling have been frustrating but not significant enough to stop my work.

I apologize aas I didn't mean to imply that it was up go you to solve all my problems. Frankly, you guys at Awesometech are downright amazing with your support I it I am sorry if I was grumpy. You dont deserve anything but gratitude.

I'm just a bit worn out.

So, that being said, if I can nail down the power issue I will be very happy as your board is really great.

So I will do some testing with your graphic and let you know what the results are.

Our thoughts are with you and yours dealing with the terrible fires. More Canucks are on the way to help.

Thanks for the instructions .

I have been debugging this for quite some time now and the other issues like stalling have been frustrating but not significant enough to stop my work.

I apologize aas I didn't mean to imply that it was up go you to solve all my problems. Frankly, you guys at Awesometech are downright amazing with your support I it I am sorry if I was grumpy. You dont deserve anything but gratitude.

I'm just a bit worn out.

So, that being said, if I can nail down the power issue I will be very happy as your board is really great.

So I will do some testing with your graphic and let you know what the results are.

Our thoughts are with you and yours dealing with the terrible fires. More Canucks are on the way to help.

Quote from Paul on January 6, 2020, 12:31 pmHi Robert,

I would suggest to isolate the power issue. Maybe you can run the board from the USB power (5v, Jp1) and the 24V DC from a separate power supply. (You can even use 12V DC).

Then the Laser power supply is only connected via the PWM, LO and GND. This should remove the electrical noise issues. Some laser power supplies have extreme issues which I guess is a quality issue from the manufacturer.

Thanks for your thoughts about the bush fires. It's extreme and we don't have any sun light, just smoke and extreme slow internet which is a challenge.

Cheers, Paul

Hi Robert,

I would suggest to isolate the power issue. Maybe you can run the board from the USB power (5v, Jp1) and the 24V DC from a separate power supply. (You can even use 12V DC).

Then the Laser power supply is only connected via the PWM, LO and GND. This should remove the electrical noise issues. Some laser power supplies have extreme issues which I guess is a quality issue from the manufacturer.

Thanks for your thoughts about the bush fires. It's extreme and we don't have any sun light, just smoke and extreme slow internet which is a challenge.

Cheers, Paul

Quote from HumptyDumpty on January 6, 2020, 12:36 pmNo apology necessary to me anyway. I'm not part of awesome tech just another mini gerbil user trying to offer some assistance and trying to understand precisely what your problems are. The graphic I showed was only one I thought you may get an consistent voltage reading, since letters or pictures would have different power levels depending on the shape & length of time the laser is active during the horizontal scans. So any consistent shape would probably work even a solid filled box.

No apology necessary to me anyway. I'm not part of awesome tech just another mini gerbil user trying to offer some assistance and trying to understand precisely what your problems are. The graphic I showed was only one I thought you may get an consistent voltage reading, since letters or pictures would have different power levels depending on the shape & length of time the laser is active during the horizontal scans. So any consistent shape would probably work even a solid filled box.