Photo's of the drag chain installed

Quote from Paul on May 6, 2018, 7:33 pmFor some people it has been difficult to understand how to install the drag chain. One even rebuild the entire drag chain solution because he could not understand how to install it (what a shame and lost time/effort).

The video is here https://youtu.be/D2wtJ8JVxko

For some people it has been difficult to understand how to install the drag chain. One even rebuild the entire drag chain solution because he could not understand how to install it (what a shame and lost time/effort).

The video is here https://youtu.be/D2wtJ8JVxko

Uploaded files:

Quote from Paul on May 6, 2018, 7:38 pmthe photo's are taken from the front of the k40. Access to the 2 allen screw is via the panel hole (some have a light there).

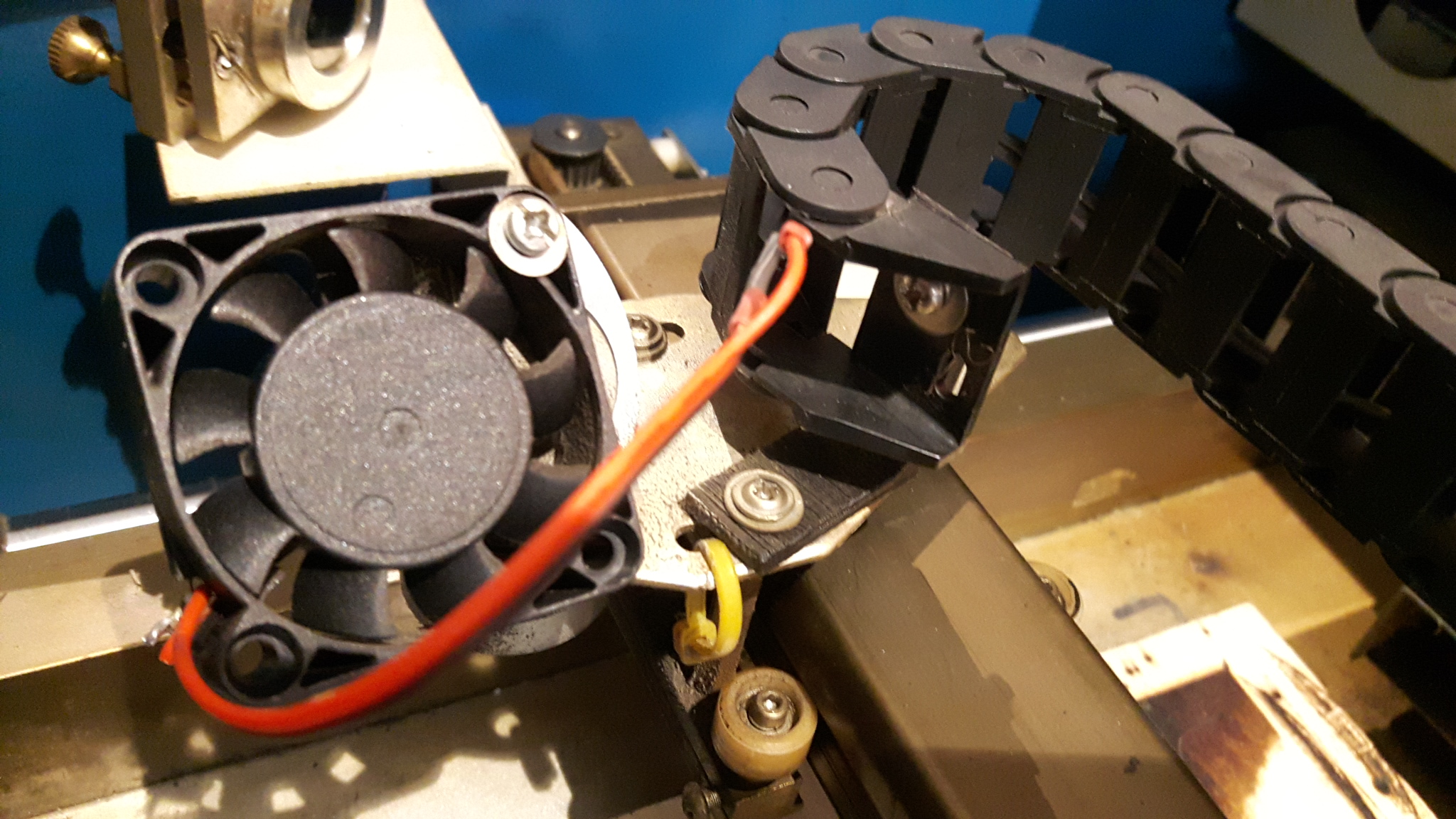

The laser head end:

The fan uses the long m4 thru the lens clip. The L shape bracket uses the existing hole in the foot plate. The chain folds into the front of the L bracket.

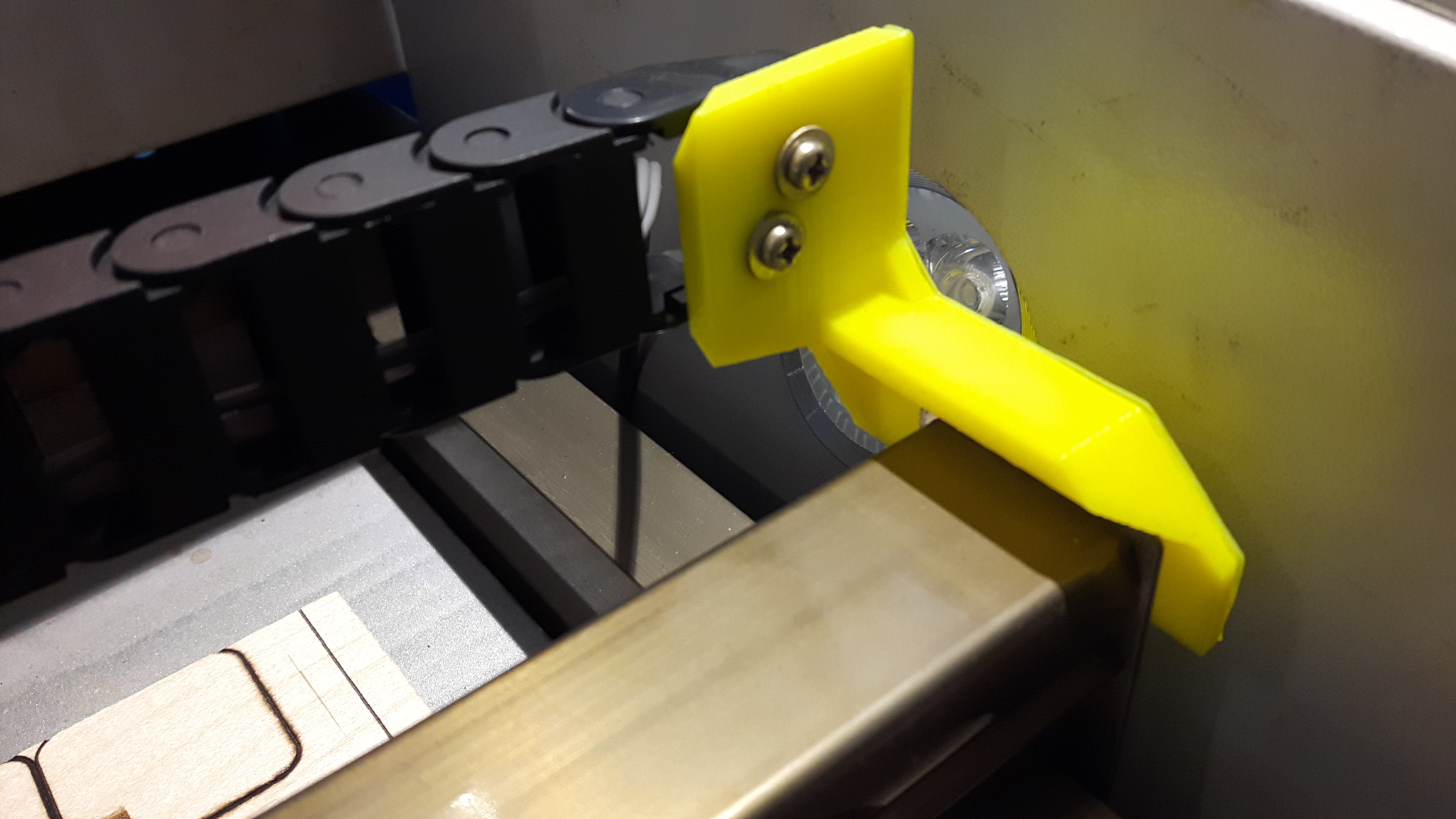

The bar end:

The chain is connected behind the bracket.

the photo's are taken from the front of the k40. Access to the 2 allen screw is via the panel hole (some have a light there).

The laser head end:

The fan uses the long m4 thru the lens clip. The L shape bracket uses the existing hole in the foot plate. The chain folds into the front of the L bracket.

The bar end:

The chain is connected behind the bracket.

Quote from Paul on May 10, 2019, 10:07 amNote that both ends of the drag chain are different. If the holes don't match then you have the wrong end of the drag chain. BTW I pre-assemble the drag chain with the brackets to avoid misunderstanding. Just align and tighten the screws.

Note that both ends of the drag chain are different. If the holes don't match then you have the wrong end of the drag chain. BTW I pre-assemble the drag chain with the brackets to avoid misunderstanding. Just align and tighten the screws.

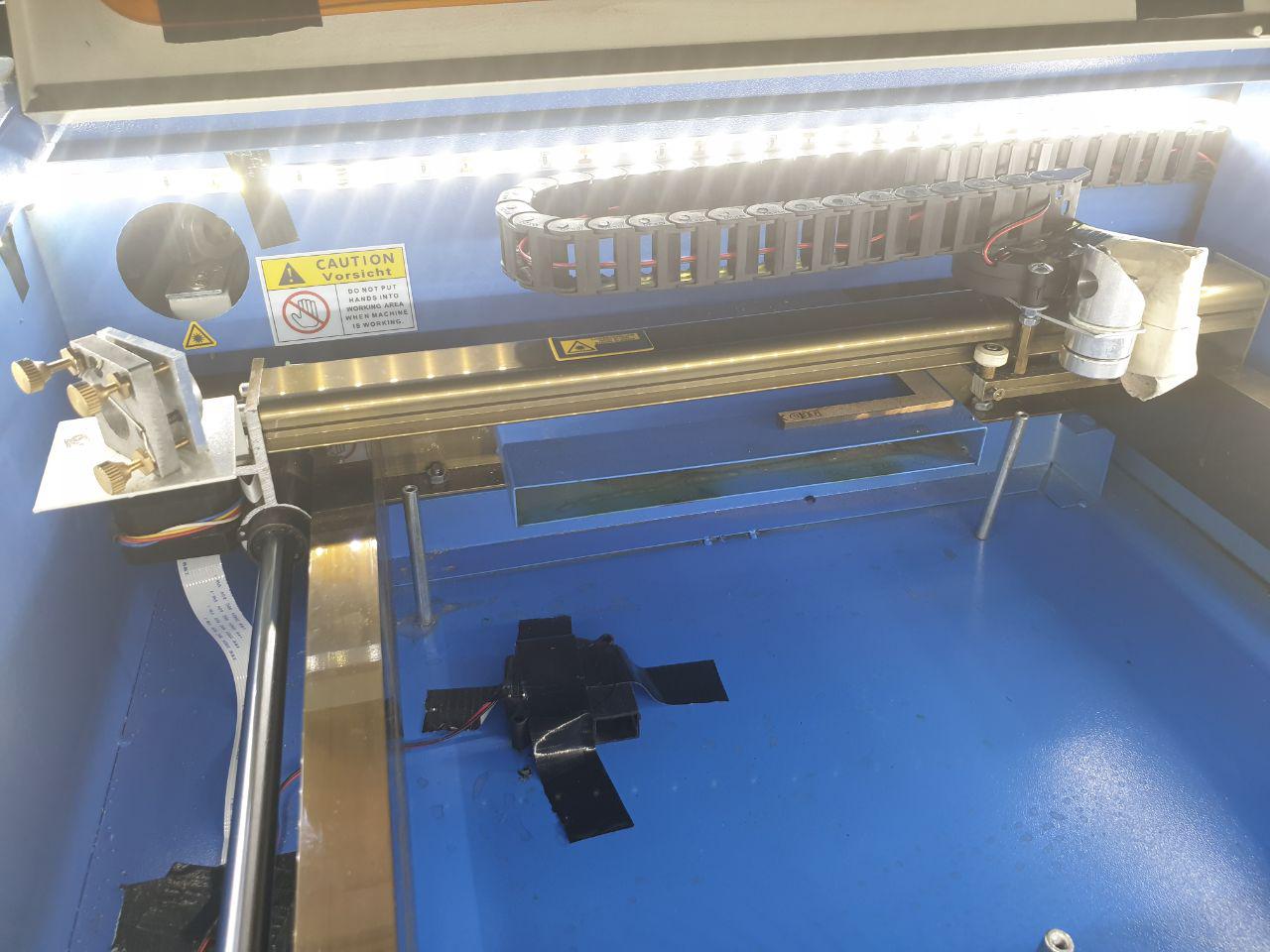

Quote from mathiaspl20 on July 31, 2019, 9:55 ambetter solution: Slightly longer drag chain mounted to the back wall. Temporary solution, it is just hot-glued in place atm, but you could easily affix it with screws. Lying axial fan on the laser head with an adjustable duct, again, temporary. Ill be running a hose through the drag chain to supply air form a remote 2 stage fan assembly in the psu section. chain works well, but i'll have to move the end on the laser head end of the drag chain to allow the chain to bend back earlier to make sure not to ever cross the laser beam. "fixed" for now by homing in top right corner.

better solution: Slightly longer drag chain mounted to the back wall. Temporary solution, it is just hot-glued in place atm, but you could easily affix it with screws. Lying axial fan on the laser head with an adjustable duct, again, temporary. Ill be running a hose through the drag chain to supply air form a remote 2 stage fan assembly in the psu section. chain works well, but i'll have to move the end on the laser head end of the drag chain to allow the chain to bend back earlier to make sure not to ever cross the laser beam. "fixed" for now by homing in top right corner.

Uploaded files:Quote from Paul on July 31, 2019, 1:13 pmBeautiful Matthias, I love it when people come up with new ideas and solution. Well done!

Beautiful Matthias, I love it when people come up with new ideas and solution. Well done!

Quote from Philip Peterman on September 9, 2019, 12:13 amMy problem is that when installed as directed the bar end mount prevents the gantry from engaging the y-axis end stop. I think I'll try Mathias' solution and mount it to the back of the case.

My problem is that when installed as directed the bar end mount prevents the gantry from engaging the y-axis end stop. I think I'll try Mathias' solution and mount it to the back of the case.

Quote from Philip Peterman on September 9, 2019, 1:25 amactually ended up just pulling out the calipers and the drill press. Works like a charm now.

actually ended up just pulling out the calipers and the drill press. Works like a charm now.