Laser won't shutoff during travel

Quote from Flex1 on June 19, 2019, 12:58 amHello,

I could really use some advice in regards to a recent controller upgrade I made. I replaced my M2 Nano to a Mini Gerbil. My laser is a K40 Laser with no notable mods. When I attempted my 1st cut, I noticed the laser appeared to never shut off and cut the “travel moves” and the laser file. I read here and google trying to find a resolution with little success. Can someone please point me in the right direction, I am new to this but eager to research and learn.NOTE: My installation consisted of unplugging all connections from the M2 Nano controller and hooking all the connections to the Mini Gerbil. I then installed Lightburn and attempted my 1st cut. It cut the file, but the laser never shutoff and the travel lines as well.

Current Firmware

Lightburn 0.9.04

Gerbil 1.1I

This is what is returned with the $$ command.

$$

$0=10

$1=255

$2=0

$3=1

$4=0

$5=1

$6=0

$7=0

(ATC M6, pulse/ff)

$8=100

(ATC Tool Td, milliseconds)

$9=100

(ATC M6 Td, milliseconds)

$10=31

$11=0.010

$12=0.002

$13=0

$19=0

(Softstart, milliseconds)

$20=0

$21=0

$22=1

$23=3

$24=2000.000

$25=2000.000

$26=250

$27=2.500

$28=5

(Spindle freq. 0 to 15)

$30=1000

$31=1

$32=1

$100=157.000

(x:stp/mm)

$101=157.000

(y:stp/mm)

$102=160.000

(z:stp/mm)

$103=160.000

(a:stp/mm)

$104=160.000

(b:stp/mm)

$110=12000.000

(x:mm/min)

$111=5000.000

(y:mm/min)

$112=5000.000

(z:mm/min)

$113=5000.000

(a:mm/min)

$114=5000.000

(b:mm/min)

$120=8000.000

(x:mm/s^2)

$121=3000.000

(y:mm/s^2)

$122=3000.000

(z:mm/s^2)

$123=3000.000

(a:mm/s^2)

$124=3000.000

(b:mm/s^2)

$130=230.000

(x:mm max)

$131=320.000

(y:mm max)

$132=200.000

(z:mm max)

$133=200.000

(a:mm max)

$134=200.000

(b:mm max)Thanks

Hello,

I could really use some advice in regards to a recent controller upgrade I made. I replaced my M2 Nano to a Mini Gerbil. My laser is a K40 Laser with no notable mods. When I attempted my 1st cut, I noticed the laser appeared to never shut off and cut the “travel moves” and the laser file. I read here and google trying to find a resolution with little success. Can someone please point me in the right direction, I am new to this but eager to research and learn.

NOTE: My installation consisted of unplugging all connections from the M2 Nano controller and hooking all the connections to the Mini Gerbil. I then installed Lightburn and attempted my 1st cut. It cut the file, but the laser never shutoff and the travel lines as well.

Current Firmware

Lightburn 0.9.04

Gerbil 1.1I

This is what is returned with the $$ command.

$$

$0=10

$1=255

$2=0

$3=1

$4=0

$5=1

$6=0

$7=0

(ATC M6, pulse/ff)

$8=100

(ATC Tool Td, milliseconds)

$9=100

(ATC M6 Td, milliseconds)

$10=31

$11=0.010

$12=0.002

$13=0

$19=0

(Softstart, milliseconds)

$20=0

$21=0

$22=1

$23=3

$24=2000.000

$25=2000.000

$26=250

$27=2.500

$28=5

(Spindle freq. 0 to 15)

$30=1000

$31=1

$32=1

$100=157.000

(x:stp/mm)

$101=157.000

(y:stp/mm)

$102=160.000

(z:stp/mm)

$103=160.000

(a:stp/mm)

$104=160.000

(b:stp/mm)

$110=12000.000

(x:mm/min)

$111=5000.000

(y:mm/min)

$112=5000.000

(z:mm/min)

$113=5000.000

(a:mm/min)

$114=5000.000

(b:mm/min)

$120=8000.000

(x:mm/s^2)

$121=3000.000

(y:mm/s^2)

$122=3000.000

(z:mm/s^2)

$123=3000.000

(a:mm/s^2)

$124=3000.000

(b:mm/s^2)

$130=230.000

(x:mm max)

$131=320.000

(y:mm max)

$132=200.000

(z:mm max)

$133=200.000

(a:mm max)

$134=200.000

(b:mm max)

Thanks

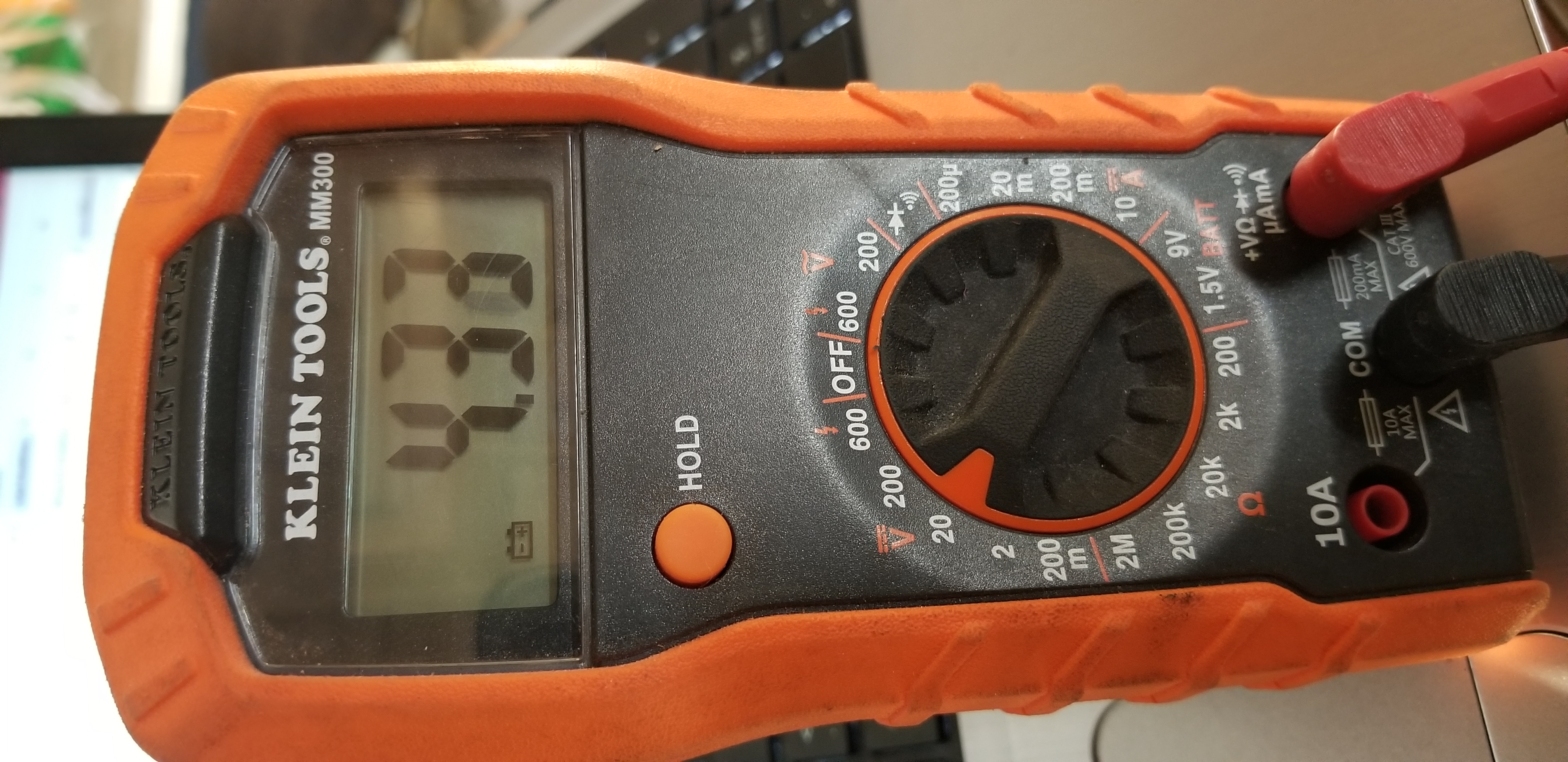

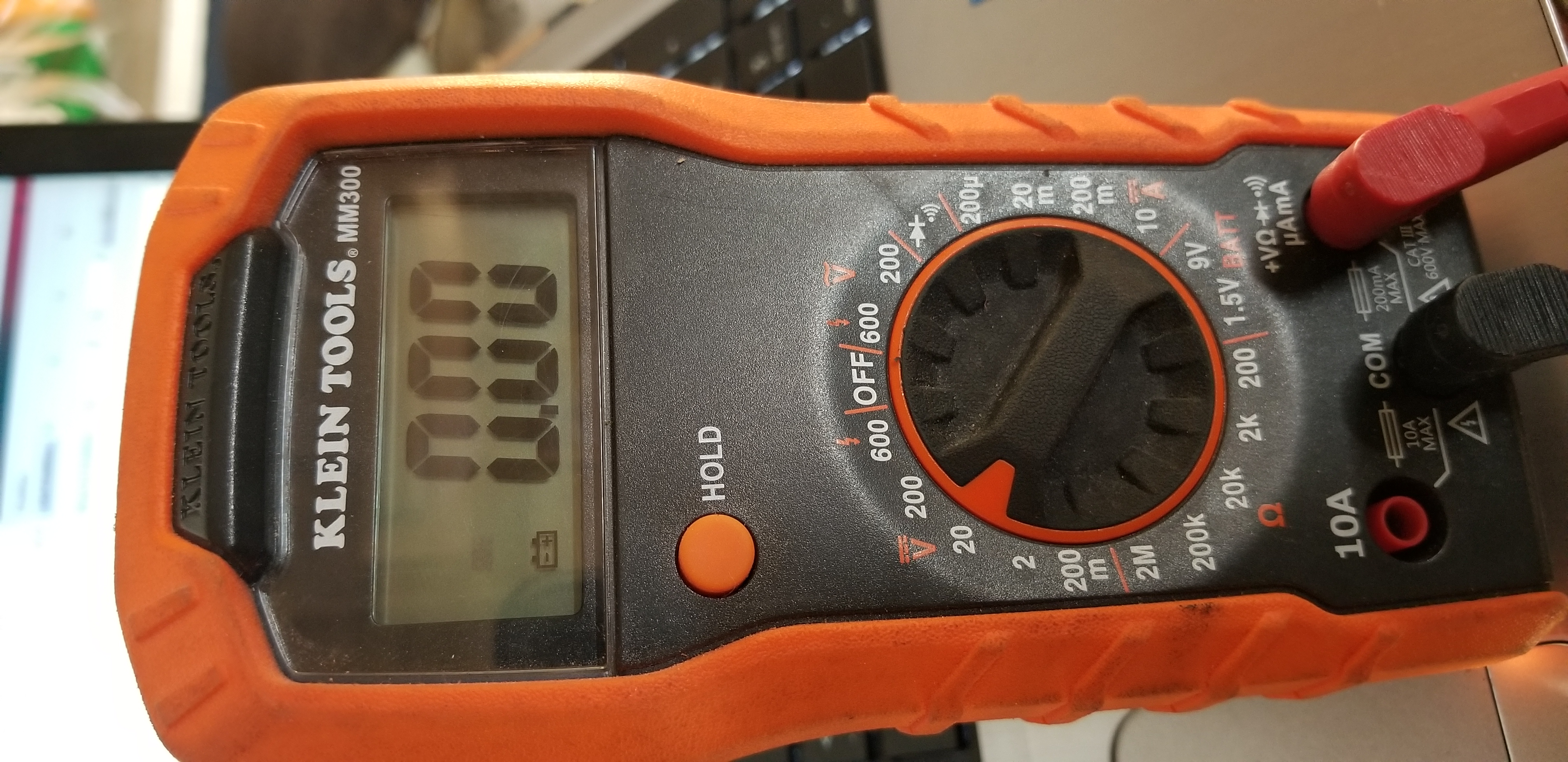

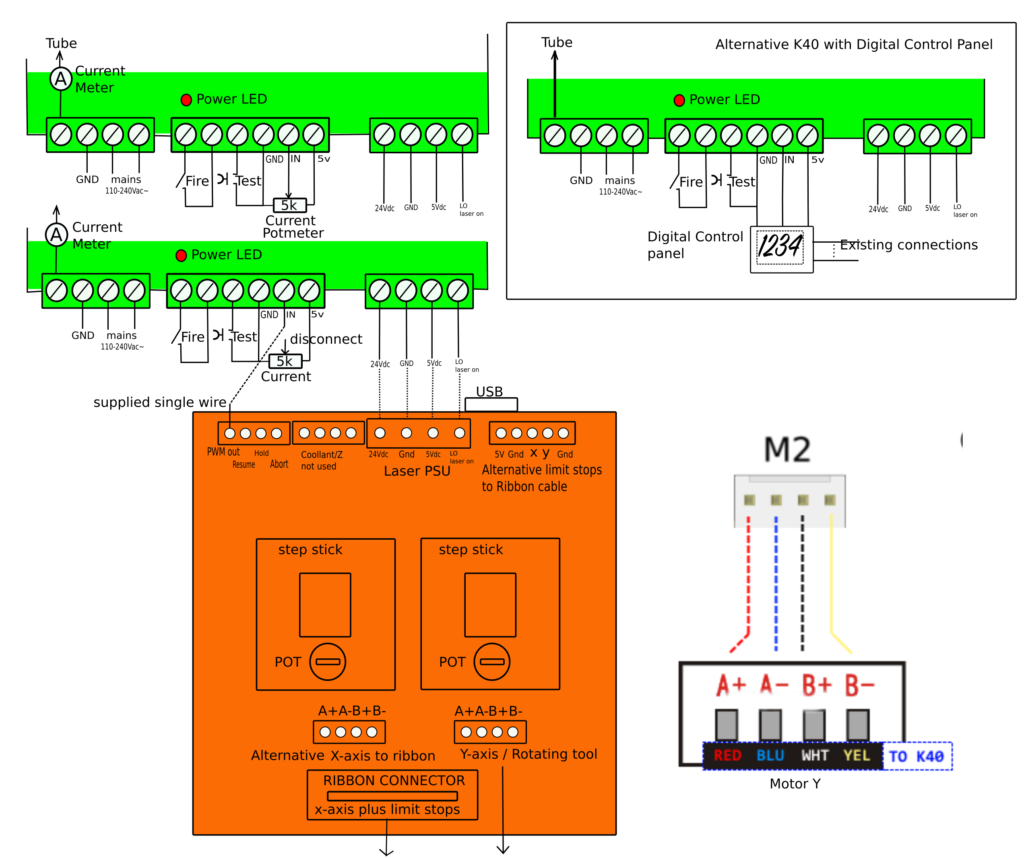

Quote from Paul on June 19, 2019, 7:47 amHi, the on/off switching during travelling is governed by the 'LO' connection. So it's possible that either the connection at the screw terminal side (first screw of the right) at the power supply is loose and/or the power connector is not sitting right on the mini Gerbil power header. A slightly misalignment or pushed out receptacle in the female connector can cause a bad connection or some resistance (faint lines during travel). You can measure with a voltmeter whether the 'LO' terminal goes to zero during cutting and up to 5V during travel. Best action is to inspect and re-seat the power plug otherwise do some measurements (DIY multimeters are cheap).

Let us know if that helped, Cheers.

Hi, the on/off switching during travelling is governed by the 'LO' connection. So it's possible that either the connection at the screw terminal side (first screw of the right) at the power supply is loose and/or the power connector is not sitting right on the mini Gerbil power header. A slightly misalignment or pushed out receptacle in the female connector can cause a bad connection or some resistance (faint lines during travel). You can measure with a voltmeter whether the 'LO' terminal goes to zero during cutting and up to 5V during travel. Best action is to inspect and re-seat the power plug otherwise do some measurements (DIY multimeters are cheap).

Let us know if that helped, Cheers.

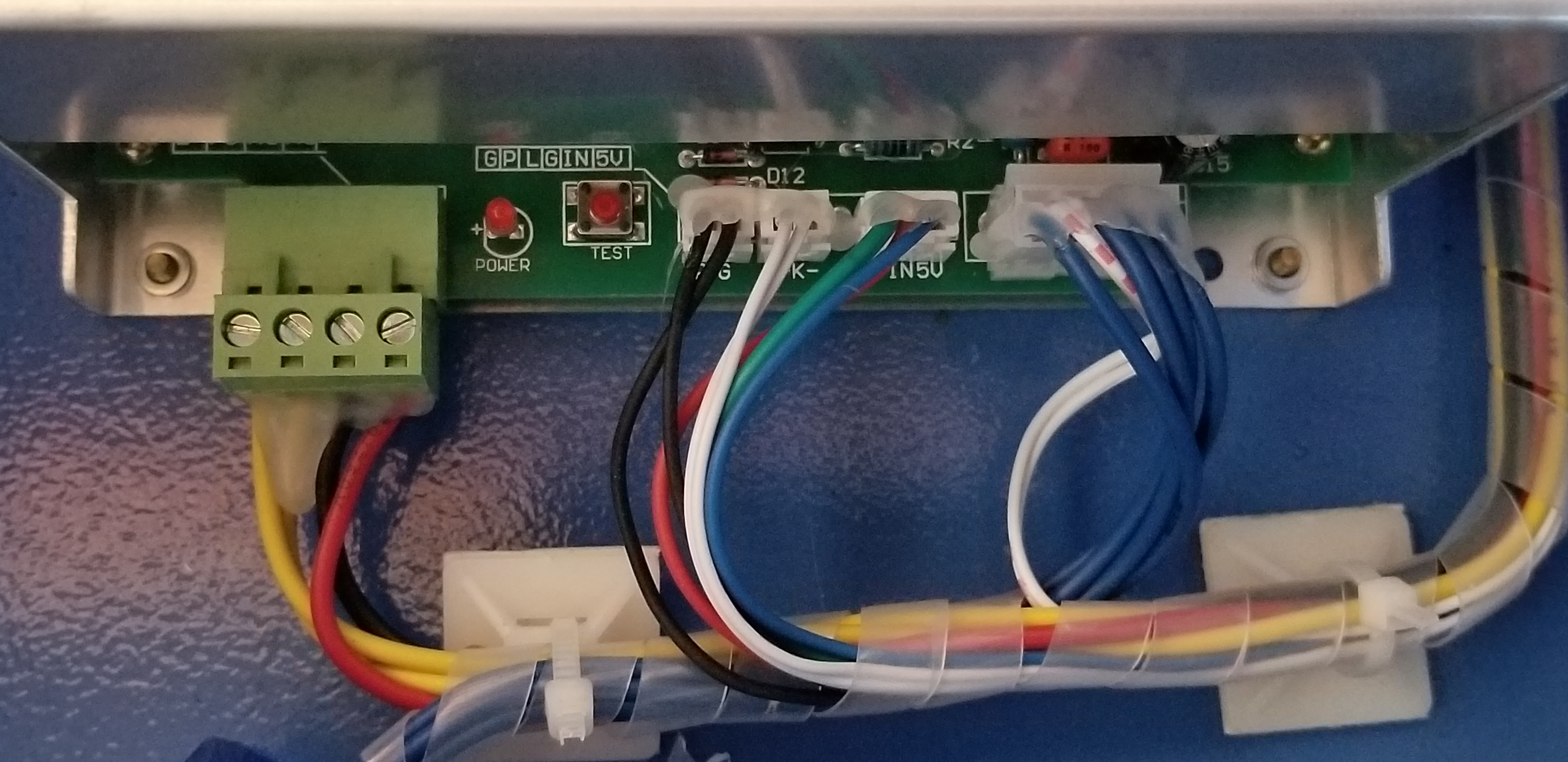

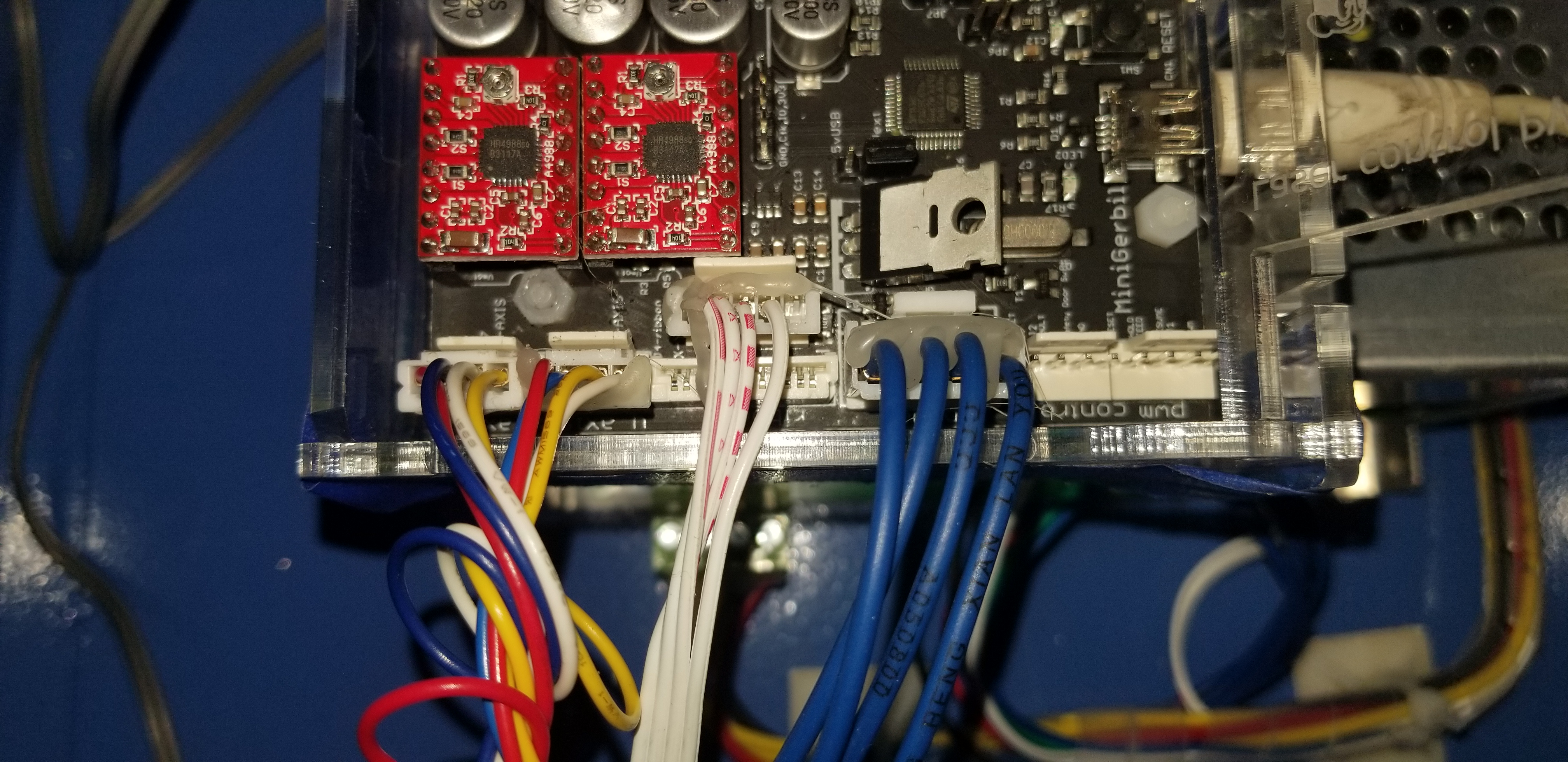

Quote from Flex1 on June 19, 2019, 12:35 pmHello, I've checked that all connections are seated firmly and I verified the voltage. The multimeter confirm zero voltage during the cut and 5v during travel, but the "travel lines" are still visible and ruining every file I've tried thus far. I've attached photos hoping someone sees my configuration error. My machine has no ribbon cable and all connections and wires are tightly seated. I'm stumped and eyes are bloodshot read from searching forums for solutions. At this point any suggestion(s) would help.

Thanks

Hello, I've checked that all connections are seated firmly and I verified the voltage. The multimeter confirm zero voltage during the cut and 5v during travel, but the "travel lines" are still visible and ruining every file I've tried thus far. I've attached photos hoping someone sees my configuration error. My machine has no ribbon cable and all connections and wires are tightly seated. I'm stumped and eyes are bloodshot read from searching forums for solutions. At this point any suggestion(s) would help.

Thanks

Uploaded files:Quote from Paul on June 19, 2019, 12:59 pmhi, I am sorry you're having trouble and make sure you rest otherwise things go wrong (I my case if I push too hard).

Let's do an experiment to see where the issue sits (board or power supply side). First of all to confirm that you're using the right device driver (STM-Gerbil). Other device drives might use different commands. You can test the M3/4 (on) and M5 (off) commands via the LB console. Ensure you set the controller in CNC mode ($32=0) when testing the M commands. In laser mode ($32=1), they only work when the gantry is moving as a safety guard.

If so, then I suggest to disconnect the LO connection (see attachments, 1 st pin on the left when looking towards the edge of the board with connectors). You might be able to tease the female receptacle out of the plastic connector case by pushing in the prong clip on the side via a miniature screw driver. Without LO to earth connected, run the same sequence. Now you should not see any lines. If they appear then the power supply has an issue otherwise it's the mini gerbil board (maybe a broken mosfet T1 see photo).

In case LO is defect then you could tie LO to ground and use the LP or WP pin as an alternative LO pin.

Let me know what you find and we take it from there (new board or reroute LO or fix power supply).

Hope this helps.

ps. More details about $ Settings are listed here What are $ Settings ?

hi, I am sorry you're having trouble and make sure you rest otherwise things go wrong (I my case if I push too hard).

Let's do an experiment to see where the issue sits (board or power supply side). First of all to confirm that you're using the right device driver (STM-Gerbil). Other device drives might use different commands. You can test the M3/4 (on) and M5 (off) commands via the LB console. Ensure you set the controller in CNC mode ($32=0) when testing the M commands. In laser mode ($32=1), they only work when the gantry is moving as a safety guard.

If so, then I suggest to disconnect the LO connection (see attachments, 1 st pin on the left when looking towards the edge of the board with connectors). You might be able to tease the female receptacle out of the plastic connector case by pushing in the prong clip on the side via a miniature screw driver. Without LO to earth connected, run the same sequence. Now you should not see any lines. If they appear then the power supply has an issue otherwise it's the mini gerbil board (maybe a broken mosfet T1 see photo).

In case LO is defect then you could tie LO to ground and use the LP or WP pin as an alternative LO pin.

Let me know what you find and we take it from there (new board or reroute LO or fix power supply).

Hope this helps.

ps. More details about $ Settings are listed here What are $ Settings ?

Uploaded files:Quote from Flex1 on June 19, 2019, 1:37 pmHi, I believe I corrected the issue. I found this photo and realize I never made a connection between PWM out to IN on the Power Supply. I totally missed it and had no clue.

Thank you and I will continue to read and get up to speed.

Hi, I believe I corrected the issue. I found this photo and realize I never made a connection between PWM out to IN on the Power Supply. I totally missed it and had no clue.

Thank you and I will continue to read and get up to speed.

Uploaded files: