Laser shot dot when going start to engrave

Quote from dancolwp1974 on April 13, 2021, 12:59 pmThanks Phil,

That's a helpful description to complement Paulo's description.

My first thought is that this isn't a common problem that I know of, so maybe related to individual installations and usage. For a K40 laser to fire, it needs its LO input set to active (Low signal) and a non-zero PWM input value.

Lightburn turns the LO to active at the start of the job, so it comes down to the value of the PWM input. If the Mini Gerbil firmware set PWM output to non-zero, then all Mini Gerbils would be affected. So it could be interference on the PWM signal. Interference could be caused by having other wires (particulary with high current) nearby to the PWM signal. Can you please send a photo of your installation, showing the Mini Gerbil and the wiring to the Power Supply?

More generally, it's very helpful if you can advise does this issue happen consistently (eg. 5 times in a row). Does it always happen, or only some days? Is it random?

Regards,

Dan

Thanks Phil,

That's a helpful description to complement Paulo's description.

My first thought is that this isn't a common problem that I know of, so maybe related to individual installations and usage. For a K40 laser to fire, it needs its LO input set to active (Low signal) and a non-zero PWM input value.

Lightburn turns the LO to active at the start of the job, so it comes down to the value of the PWM input. If the Mini Gerbil firmware set PWM output to non-zero, then all Mini Gerbils would be affected. So it could be interference on the PWM signal. Interference could be caused by having other wires (particulary with high current) nearby to the PWM signal. Can you please send a photo of your installation, showing the Mini Gerbil and the wiring to the Power Supply?

More generally, it's very helpful if you can advise does this issue happen consistently (eg. 5 times in a row). Does it always happen, or only some days? Is it random?

Regards,

Dan

Quote from Phil Freeman on April 13, 2021, 10:41 pmHiya Dan,

Thank you for the response. I take some pics over the next few days. shame there's no way to show a video of it happening.

what I will do is start it from the home position but will place a bit of white card underneath to see if the tube fires the moment I press start on a job.

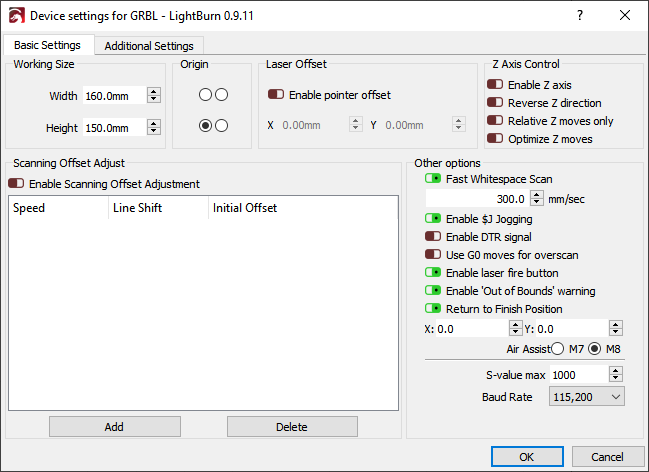

there was one funny thing that happened and I might post it up on the lightburn group. I was engraving a vector file . this had a circle around the perimeter. it would only engrave the top and bottom of the circle. but was fine on a BMP file. trying to get to the bottom of this I looked at the devise setting in lightburn. there's a TAB in there that says read settings from controller. I click this and the settings changed. funny enough the vector started to engrave correct.

The funny part is the header of the setting states it's only to help predict timing of jobs and doesn't actually change anything physical on the controller or the way lightburn behaves.

Yet it seemed to do something. that was when I noticed a dot being fired then I press start on a job. it may have nothing to do with it and could have been happening for months and I never noticed. strange!

Ill get the pics posted as soon as I can.

Phil

Hiya Dan,

Thank you for the response. I take some pics over the next few days. shame there's no way to show a video of it happening.

what I will do is start it from the home position but will place a bit of white card underneath to see if the tube fires the moment I press start on a job.

there was one funny thing that happened and I might post it up on the lightburn group. I was engraving a vector file . this had a circle around the perimeter. it would only engrave the top and bottom of the circle. but was fine on a BMP file. trying to get to the bottom of this I looked at the devise setting in lightburn. there's a TAB in there that says read settings from controller. I click this and the settings changed. funny enough the vector started to engrave correct.

The funny part is the header of the setting states it's only to help predict timing of jobs and doesn't actually change anything physical on the controller or the way lightburn behaves.

Yet it seemed to do something. that was when I noticed a dot being fired then I press start on a job. it may have nothing to do with it and could have been happening for months and I never noticed. strange!

Ill get the pics posted as soon as I can.

Phil

Quote from dancolwp1974 on April 13, 2021, 10:47 pmYou're welcome Phil.

When adding some more PWM configuration options for users (typically relevant for DIY laser diode users) in the most recent firmware, we took the opportunity to review the PWM control code and made some tweaks to provide an extra layer of protection against this sort of issue occuring. So, if you're able, you could perform the firmware upgrade and see if that helps.

See https://awesome.tech/release-note-mg-firmware-update-12353/

Regards,

Dan

You're welcome Phil.

When adding some more PWM configuration options for users (typically relevant for DIY laser diode users) in the most recent firmware, we took the opportunity to review the PWM control code and made some tweaks to provide an extra layer of protection against this sort of issue occuring. So, if you're able, you could perform the firmware upgrade and see if that helps.

See https://awesome.tech/release-note-mg-firmware-update-12353/

Regards,

Dan

Quote from Phil Freeman on April 13, 2021, 10:48 pmIn the Additional settings tab

"The Additional Settings page contains settings used by the preview simulation engine to calculate acceleration timing, traversal speeds, and enforce speed limits when computing the time it will take to complete a job, and when simulating the job. These must currently be set manually by the user to match your controller settings, though our goal is to handle this automatically if possible"

In the Additional settings tab

"The Additional Settings page contains settings used by the preview simulation engine to calculate acceleration timing, traversal speeds, and enforce speed limits when computing the time it will take to complete a job, and when simulating the job. These must currently be set manually by the user to match your controller settings, though our goal is to handle this automatically if possible"

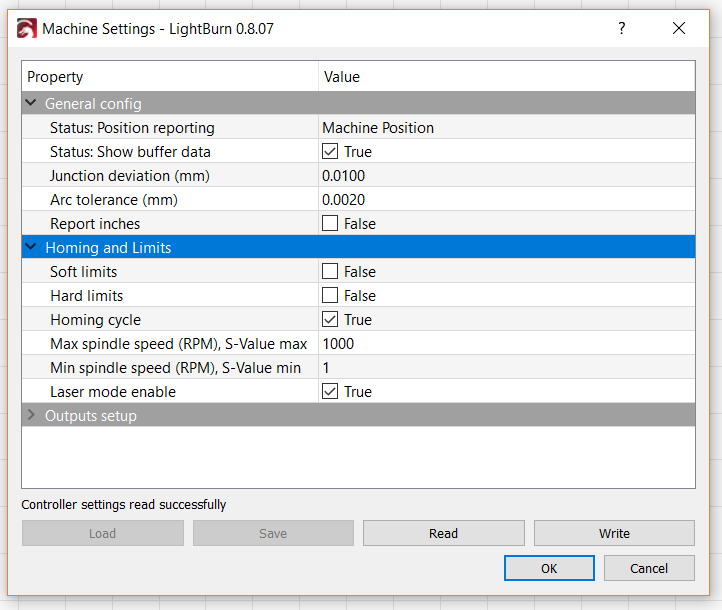

Uploaded files:Quote from dancolwp1974 on April 13, 2021, 10:57 pmInteresing!

If you don't mind trying, could you please open up the menu shown below and try changing min spindle speed to 5, see if that works.

Interesing!

If you don't mind trying, could you please open up the menu shown below and try changing min spindle speed to 5, see if that works.

Quote from Phil Freeman on April 15, 2021, 12:49 amI will give it a go Dan, and will try updating the firmware as soon as I can get the STM lead. £4.99 here in England off amazon.

I've taken a few pictures but I'm on my work machine at the moment so can't upload them. but I'll get a better chance the weekend, when I do most of my messing about on the K40. I mainly use to to help with my leather hobby. Tho I'm a Cam Engineer in the circuit board industry by trade. last thing I like to do it sit in front of a computer when I get home haha.

I will give it a go Dan, and will try updating the firmware as soon as I can get the STM lead. £4.99 here in England off amazon.

I've taken a few pictures but I'm on my work machine at the moment so can't upload them. but I'll get a better chance the weekend, when I do most of my messing about on the K40. I mainly use to to help with my leather hobby. Tho I'm a Cam Engineer in the circuit board industry by trade. last thing I like to do it sit in front of a computer when I get home haha.