Help with settings

Quote from wvarga on April 16, 2019, 3:37 amI've been working on getting my mini geribil set up with Laserweb but have a few problems. I'm not sure which of all these are related or how but:

1. When I home the K40, the y axis seems to work fine, but the x axis will only tick back maybe a couple mm. I'm new to all this so I'm not sure if this is related but when I jog the laser head back to the home position manually it seems to ignore the limit switches, which are mechanical.

2. In the settings I moved the offset of the machine to -200 for the x axis. Is this right?, it looks right but seemingly every G Code I generate says that it is out of machine bounds and may halt.

3. Somewhere in the begenning of a job it likes to stop and give a check door warning. Not sure how to get rid of this, I have nothing plugged into the safety door plug on the gerbil currently.

4. I get error 1 & 2 very often as well.

I have just a few times gotten through a job without any errors stopping me. Could someone also please post the gerbil settings for me as well?

Thank you so much in advance for any help

I've been working on getting my mini geribil set up with Laserweb but have a few problems. I'm not sure which of all these are related or how but:

1. When I home the K40, the y axis seems to work fine, but the x axis will only tick back maybe a couple mm. I'm new to all this so I'm not sure if this is related but when I jog the laser head back to the home position manually it seems to ignore the limit switches, which are mechanical.

2. In the settings I moved the offset of the machine to -200 for the x axis. Is this right?, it looks right but seemingly every G Code I generate says that it is out of machine bounds and may halt.

3. Somewhere in the begenning of a job it likes to stop and give a check door warning. Not sure how to get rid of this, I have nothing plugged into the safety door plug on the gerbil currently.

4. I get error 1 & 2 very often as well.

I have just a few times gotten through a job without any errors stopping me. Could someone also please post the gerbil settings for me as well?

Thank you so much in advance for any help

Quote from Paul on April 16, 2019, 8:24 pmOkay it seems that your limit switches have a bigger hysteresis distance than configured by default (2.5mm).

Set $27 to something like 4mm and see if that works for you (if it does than try to mimise the pull off switch distance as much as possible to avoid loss of working area). If that still cuase problems than increase it even further like 5mm until it works (e.g. homing is successful) .

If homing fails then test the limit switches (Normally open or normally closed) and configure the limit switch invert setting $5. See the blog about setting for all details What are $ Settings ?

Okay it seems that your limit switches have a bigger hysteresis distance than configured by default (2.5mm).

Set $27 to something like 4mm and see if that works for you (if it does than try to mimise the pull off switch distance as much as possible to avoid loss of working area). If that still cuase problems than increase it even further like 5mm until it works (e.g. homing is successful) .

If homing fails then test the limit switches (Normally open or normally closed) and configure the limit switch invert setting $5. See the blog about setting for all details What are $ Settings ?

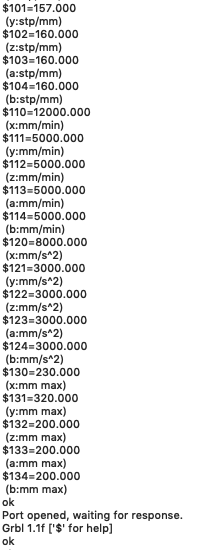

Quote from Paul on April 16, 2019, 8:31 pmCNCjs 1.9.15 [Grbl]

Connected to COM324 with a baud rate of 115200

Grbl 1.1f ['$' for help]

client> $$

$0=10 (Step pulse time, microseconds)

$1=255 (Step idle delay, milliseconds)

$2=0 (Step pulse invert, mask)

$3=1 (Step direction invert, mask)

$4=0 (Invert step enable pin, boolean)

$5=1 (Invert limit pins, boolean)

$6=0 (Invert probe pin, boolean)

$7=0 (ATC M6, pulse/ff , just for CNC )

$8=100 (ATC Tool Td, milliseconds just for CNC )

$9=100 (ATC M6 Td, milliseconds, just for CNC)

$10=31 (Status report options, mask)

$11=0.010 (Junction deviation, millimeters)

$12=0.002 (Arc tolerance, millimeters)

$13=0 (Report in inches, boolean)

$19=0 (Softstart, milliseconds, just for CNC spindles)

$20=0 (Soft limits enable, boolean)

$21=0 (Hard limits enable, boolean)

$22=1 (Homing cycle enable, boolean)

$23=3 (Homing direction invert, mask)

$24=2000.000 (Homing locate feed rate, mm/min)

$25=2000.000 (Homing search seek rate, mm/min)

$26=250 (Homing switch debounce delay, milliseconds)

$27=2.500 (Homing switch pull-off distance, millimeters)

$28=5 (Spindle freq. 0 to 15) - 5 = 1000kHz

$30=1000 (Maximum spindle speed, RPM)

$31=1 (Minimum spindle speed, RPM)

$32=1 (Laser-mode enable, boolean)

$100=157.000 (X-axis travel resolution, step/mm)

(x:stp/mm)

$101=157.000 (Y-axis travel resolution, step/mm)

(y:stp/mm)

$102=160.000 (Z-axis travel resolution, step/mm)

(z:stp/mm)

$103=160.000 (a:stp/mm)

$104=160.000 (b:stp/mm)

$110=12000.000 (X-axis maximum rate, mm/min)

(x:mm/min)

$111=5000.000 (Y-axis maximum rate, mm/min)

(y:mm/min)

$112=5000.000 (Z-axis maximum rate, mm/min)

(z:mm/min)

$113=5000.000 (a:mm/min)

$114=5000.000 (b:mm/min)

$120=8000.000 (X-axis acceleration, mm/sec^2)

(x:mm/s^2)

$121=3000.000 (Y-axis acceleration, mm/sec^2)

(y:mm/s^2)

$122=3000.000 (Z-axis acceleration, mm/sec^2)

(z:mm/s^2)

$123=3000.000 (a:mm/s^2)

$124=3000.000 (b:mm/s^2)

$130=230.000 (X-axis maximum travel, millimeters)

(x:mm max)

$131=320.000 (Y-axis maximum travel, millimeters)

(y:mm max)

$132=200.000 (Z-axis maximum travel, millimeters)

(z:mm max)

$133=200.000 (a:mm max)

$134=200.000 (b:mm max)

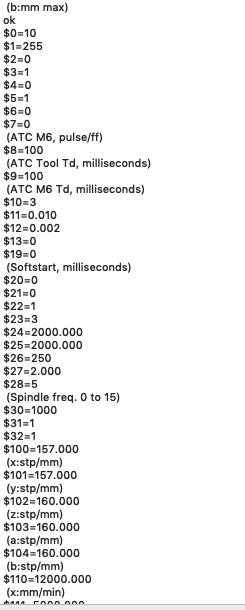

CNCjs 1.9.15 [Grbl]

Connected to COM324 with a baud rate of 115200

Grbl 1.1f ['$' for help]

client> $$

$0=10 (Step pulse time, microseconds)

$1=255 (Step idle delay, milliseconds)

$2=0 (Step pulse invert, mask)

$3=1 (Step direction invert, mask)

$4=0 (Invert step enable pin, boolean)

$5=1 (Invert limit pins, boolean)

$6=0 (Invert probe pin, boolean)

$7=0 (ATC M6, pulse/ff , just for CNC )

$8=100 (ATC Tool Td, milliseconds just for CNC )

$9=100 (ATC M6 Td, milliseconds, just for CNC)

$10=31 (Status report options, mask)

$11=0.010 (Junction deviation, millimeters)

$12=0.002 (Arc tolerance, millimeters)

$13=0 (Report in inches, boolean)

$19=0 (Softstart, milliseconds, just for CNC spindles)

$20=0 (Soft limits enable, boolean)

$21=0 (Hard limits enable, boolean)

$22=1 (Homing cycle enable, boolean)

$23=3 (Homing direction invert, mask)

$24=2000.000 (Homing locate feed rate, mm/min)

$25=2000.000 (Homing search seek rate, mm/min)

$26=250 (Homing switch debounce delay, milliseconds)

$27=2.500 (Homing switch pull-off distance, millimeters)

$28=5 (Spindle freq. 0 to 15) - 5 = 1000kHz

$30=1000 (Maximum spindle speed, RPM)

$31=1 (Minimum spindle speed, RPM)

$32=1 (Laser-mode enable, boolean)

$100=157.000 (X-axis travel resolution, step/mm)

(x:stp/mm)

$101=157.000 (Y-axis travel resolution, step/mm)

(y:stp/mm)

$102=160.000 (Z-axis travel resolution, step/mm)

(z:stp/mm)

$103=160.000 (a:stp/mm)

$104=160.000 (b:stp/mm)

$110=12000.000 (X-axis maximum rate, mm/min)

(x:mm/min)

$111=5000.000 (Y-axis maximum rate, mm/min)

(y:mm/min)

$112=5000.000 (Z-axis maximum rate, mm/min)

(z:mm/min)

$113=5000.000 (a:mm/min)

$114=5000.000 (b:mm/min)

$120=8000.000 (X-axis acceleration, mm/sec^2)

(x:mm/s^2)

$121=3000.000 (Y-axis acceleration, mm/sec^2)

(y:mm/s^2)

$122=3000.000 (Z-axis acceleration, mm/sec^2)

(z:mm/s^2)

$123=3000.000 (a:mm/s^2)

$124=3000.000 (b:mm/s^2)

$130=230.000 (X-axis maximum travel, millimeters)

(x:mm max)

$131=320.000 (Y-axis maximum travel, millimeters)

(y:mm max)

$132=200.000 (Z-axis maximum travel, millimeters)

(z:mm max)

$133=200.000 (a:mm max)

$134=200.000 (b:mm max)

Quote from wvarga on April 17, 2019, 2:08 amAwesome thank you for the info! I did play around with the pull off setting and had eventually brought it past 5mm but it still did the same thing.

Any idea why I am getting multiple 'check door' errors?

Awesome thank you for the info! I did play around with the pull off setting and had eventually brought it past 5mm but it still did the same thing.

Any idea why I am getting multiple 'check door' errors?

Quote from Paul on April 17, 2019, 9:01 amHi, There are additional pins on the mini gerbil for pause, resume and door. If these are not connected, you should not get any 'check door' messages. If you have connected it (for example to put a switch under the lid of the k40 door) then it might pick up electrical noise. Use a 100nF cap in parallel with the switch.

If you have not connected any door switch then I suspect a floating K40 earth. Check the connection between middle safety prong of your mains plug and the chassis of the k40 with an Ohm meter. It should conduct (less than 1 Ohm). If not, then the chassis is floating and correct (life hazzard!!!!). Let us know what you found.

Hi, There are additional pins on the mini gerbil for pause, resume and door. If these are not connected, you should not get any 'check door' messages. If you have connected it (for example to put a switch under the lid of the k40 door) then it might pick up electrical noise. Use a 100nF cap in parallel with the switch.

If you have not connected any door switch then I suspect a floating K40 earth. Check the connection between middle safety prong of your mains plug and the chassis of the k40 with an Ohm meter. It should conduct (less than 1 Ohm). If not, then the chassis is floating and correct (life hazzard!!!!). Let us know what you found.

Quote from wvarga on April 18, 2019, 1:59 amFixed it! Turns out the y axis limit switch had a loose connection, but seems to be all good now. Settings were easy to set up once I got that working

Thank you so much for all your help Paul

Fixed it! Turns out the y axis limit switch had a loose connection, but seems to be all good now. Settings were easy to set up once I got that working

Thank you so much for all your help Paul

Quote from wvarga on April 27, 2019, 1:47 amHey Paul

I got a couple things I still am trying to smooth out. The laser turns on as it is making its way to the job site, and I frequently get error 2 & 11, bad number format and line overflow. All my settings look as they should, as well as the G Code, to my limited understanding.

Hey Paul

I got a couple things I still am trying to smooth out. The laser turns on as it is making its way to the job site, and I frequently get error 2 & 11, bad number format and line overflow. All my settings look as they should, as well as the G Code, to my limited understanding.

Quote from Paul on April 27, 2019, 8:17 amThese are communication issues. Either replace the USB cable for a shorter one, make sure you have a grounded k40 chassis or you could set the jumper on the board from ext5v to usb5v. If that does not help, have a look at your computer specs (performance, swap with another more powerful pc and see if that improves) and/or close down some programs and see if that helps. Pls let me know your findings and I might be able to hint to a solution.

Cheers, Paul

These are communication issues. Either replace the USB cable for a shorter one, make sure you have a grounded k40 chassis or you could set the jumper on the board from ext5v to usb5v. If that does not help, have a look at your computer specs (performance, swap with another more powerful pc and see if that improves) and/or close down some programs and see if that helps. Pls let me know your findings and I might be able to hint to a solution.

Cheers, Paul

Quote from wvarga on April 27, 2019, 1:19 pmThanks for your quick reply Paul! Fixed it!

I confirmed it was grounded and also replaced the usb cable with a new beefier one but the problems kept up. I then was going through my settings again to post them and realized I had "$30=1000 (Maximum spindle speed, RPM)" as '=0', which not sure why the hell I had done that but.. I flipped that back up to 1000 and bam! everything seems to be perfect now.

For any other dull crayons out there looking for a sharpener this has seemingly fixed my check door, error 2, 11, and no error mid job stalls, as well as a host of other random issues. It has been working great now no issues with LaserWeb CNCjs LightBurn.

Stoked I didn't give up, I learned a lot. I'll be sure to post my Catan board when I slice that sucker up

Thanks for your quick reply Paul! Fixed it!

I confirmed it was grounded and also replaced the usb cable with a new beefier one but the problems kept up. I then was going through my settings again to post them and realized I had "$30=1000 (Maximum spindle speed, RPM)" as '=0', which not sure why the hell I had done that but.. I flipped that back up to 1000 and bam! everything seems to be perfect now.

For any other dull crayons out there looking for a sharpener this has seemingly fixed my check door, error 2, 11, and no error mid job stalls, as well as a host of other random issues. It has been working great now no issues with LaserWeb CNCjs LightBurn.

Stoked I didn't give up, I learned a lot. I'll be sure to post my Catan board when I slice that sucker up

Quote from wvarga on June 1, 2019, 12:13 pmHey Paul/Everyone, hope its ok I add on to this thread with a new problem, which may be the settings..,,

I've been using the laser almost daily since you helped me figure out the settings and has so far been flawless until a few days ago. I was in the middle of a job which was going fine for about the first 15 minutes or so, then noticed the laser had stopped firing but the laser head was still moving like normal. After restarting everything, the laser would still not fire and the machine origin had moved itself to X 257.52, Y 53.13, which is super strange to me. I didn't figure out how to zero that back out until I tried testing in CNCjs, from LightBurn.

Since zeroing that out and doing my research online, I triple checked my connections, replaced my PWM wire and made sure of the connection, replaced my PSU (Based on no cracks in the tube I tried this), and have gone through my settings over and over (screenshots attached). The new PSU also has the test button, which helped me confirm that the laser tube is working. Also attached are photos of my mini grbl connections and PSU, and please note that it looks unbolted and messy because as I took these earlier when I was working with the PSU.

Currently, everything seems to be operational now, except for the laser fire. My next step was going to be to hook up the old controller and try that but wanted to reach out to the forums before doing do so as it generally doesn't like fun right now..

Also stoked you have US shipping now! As i'm cranking away on a sort of time sensitive project I would be eager and happy to order a new one if you think I may have fried it or something.

Any and all help is appreciated!

Hey Paul/Everyone, hope its ok I add on to this thread with a new problem, which may be the settings..,,

I've been using the laser almost daily since you helped me figure out the settings and has so far been flawless until a few days ago. I was in the middle of a job which was going fine for about the first 15 minutes or so, then noticed the laser had stopped firing but the laser head was still moving like normal. After restarting everything, the laser would still not fire and the machine origin had moved itself to X 257.52, Y 53.13, which is super strange to me. I didn't figure out how to zero that back out until I tried testing in CNCjs, from LightBurn.

Since zeroing that out and doing my research online, I triple checked my connections, replaced my PWM wire and made sure of the connection, replaced my PSU (Based on no cracks in the tube I tried this), and have gone through my settings over and over (screenshots attached). The new PSU also has the test button, which helped me confirm that the laser tube is working. Also attached are photos of my mini grbl connections and PSU, and please note that it looks unbolted and messy because as I took these earlier when I was working with the PSU.

Currently, everything seems to be operational now, except for the laser fire. My next step was going to be to hook up the old controller and try that but wanted to reach out to the forums before doing do so as it generally doesn't like fun right now..

Also stoked you have US shipping now! As i'm cranking away on a sort of time sensitive project I would be eager and happy to order a new one if you think I may have fried it or something.

Any and all help is appreciated!

Uploaded files:

Quote from wvarga on June 4, 2019, 3:45 amFixed it after corresponding with Dan via email:

Hey Dan thank you so much for helping me out, I finally fixed it!I went through your grounding checklist and now i'm not sure if it was my first PSU or a grounding wire that went bad, but its working now regardless. The laser came back on after switching out the ground between mini gerbil and the PSU (Which is this supposed to be hooked up? I don't remember it from the installation instructions), and adding a bridge between the left two pins of the 6 pin socket on the PSU, the G & P pins?Works like a charm again! Thank you a bunch!

Fixed it after corresponding with Dan via email:

Quote from wvarga on June 4, 2019, 11:38 amAlso to clarify for others, the ground wire I mention in the post above was from the pins with PWM control, which I didn't have hooked up in those photos.

Also to clarify for others, the ground wire I mention in the post above was from the pins with PWM control, which I didn't have hooked up in those photos.