Bad Laser Tube???

Quote from Flex1 on June 24, 2019, 6:16 amHello,

I have a K40 Laser with less than 10 hours total usage. Newly installed Mini Gerbil 1.1 Controller and Lightburn 0.9.04

Yesterday I was able to cut through 5.68 mm Acrylic at speed 0.20 in./sec. and 65% power.

Today I tried to cut through 2.84 mm Acrylic at 0.20 in./sec. and 100% power and it didn't cut through even after 6 cuts total.

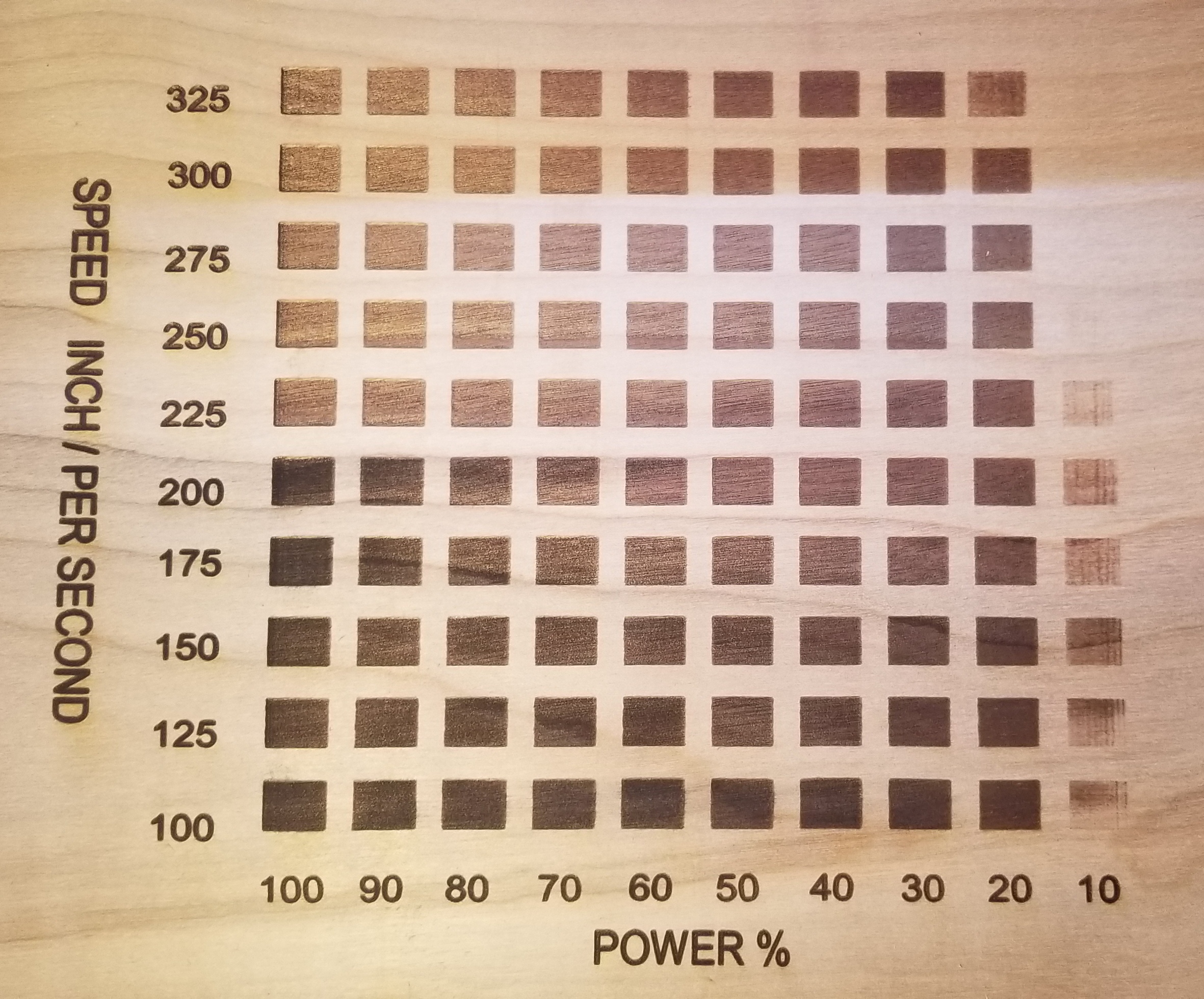

I ran a laser power test file (included photo) and it looks like I have some type of power supply, laser tube or settings problem.

Has anyone ever experienced this problem, understand what symptoms may mean or can point me in the correct direction for better understand.

NOTE: These are the returned $$ setting values. These are default because I don't know how to modify and save the settings as of yet.

$0=10

$1=255

$2=0

$3=1

$4=0

$5=1

$6=0

$7=0

(ATC M6, pulse/ff)

$8=100

(ATC Tool Td, milliseconds)

$9=100

(ATC M6 Td, milliseconds)

$10=31

$11=0.010

$12=0.002

$13=0

$19=0

(Softstart, milliseconds)

$20=0

$21=0

$22=1

$23=3

$24=2000.000

$25=2000.000

$26=250

$27=2.500

$28=5

(Spindle freq. 0 to 15)

$30=1000

$31=1

$32=1

$100=157.000

(x:stp/mm)

$101=157.000

(y:stp/mm)

$102=160.000

(z:stp/mm)

$103=160.000

(a:stp/mm)

$104=160.000

(b:stp/mm)

$110=12000.000

(x:mm/min)

$111=5000.000

(y:mm/min)

$112=5000.000

(z:mm/min)

$113=5000.000

(a:mm/min)

$114=5000.000

(b:mm/min)

$120=8000.000

(x:mm/s^2)

$121=3000.000

(y:mm/s^2)

$122=3000.000

(z:mm/s^2)

$123=3000.000

(a:mm/s^2)

$124=3000.000

(b:mm/s^2)

$130=230.000

(x:mm max)

$131=320.000

(y:mm max)

$132=200.000

(z:mm max)

$133=200.000

(a:mm max)

$134=200.000

(b:mm max)

Thanks,

Hello,

I have a K40 Laser with less than 10 hours total usage. Newly installed Mini Gerbil 1.1 Controller and Lightburn 0.9.04

Yesterday I was able to cut through 5.68 mm Acrylic at speed 0.20 in./sec. and 65% power.

Today I tried to cut through 2.84 mm Acrylic at 0.20 in./sec. and 100% power and it didn't cut through even after 6 cuts total.

I ran a laser power test file (included photo) and it looks like I have some type of power supply, laser tube or settings problem.

Has anyone ever experienced this problem, understand what symptoms may mean or can point me in the correct direction for better understand.

NOTE: These are the returned $$ setting values. These are default because I don't know how to modify and save the settings as of yet.

$0=10

$1=255

$2=0

$3=1

$4=0

$5=1

$6=0

$7=0

(ATC M6, pulse/ff)

$8=100

(ATC Tool Td, milliseconds)

$9=100

(ATC M6 Td, milliseconds)

$10=31

$11=0.010

$12=0.002

$13=0

$19=0

(Softstart, milliseconds)

$20=0

$21=0

$22=1

$23=3

$24=2000.000

$25=2000.000

$26=250

$27=2.500

$28=5

(Spindle freq. 0 to 15)

$30=1000

$31=1

$32=1

$100=157.000

(x:stp/mm)

$101=157.000

(y:stp/mm)

$102=160.000

(z:stp/mm)

$103=160.000

(a:stp/mm)

$104=160.000

(b:stp/mm)

$110=12000.000

(x:mm/min)

$111=5000.000

(y:mm/min)

$112=5000.000

(z:mm/min)

$113=5000.000

(a:mm/min)

$114=5000.000

(b:mm/min)

$120=8000.000

(x:mm/s^2)

$121=3000.000

(y:mm/s^2)

$122=3000.000

(z:mm/s^2)

$123=3000.000

(a:mm/s^2)

$124=3000.000

(b:mm/s^2)

$130=230.000

(x:mm max)

$131=320.000

(y:mm max)

$132=200.000

(z:mm max)

$133=200.000

(a:mm max)

$134=200.000

(b:mm max)

Thanks,

Uploaded files:Quote from Paul on June 25, 2019, 3:05 pmOkay, this can be caused by many things. I normally check the lens and mirrors. A speck of dust or debris from a previous laser job can drop the power considerably.

Also check the wiring (pwm/ground) and for loose screw terminals on the power supply.

Ideally you should keep a log of hours ran on the tube. They last for about 1000 hours although better quality brands last longer.

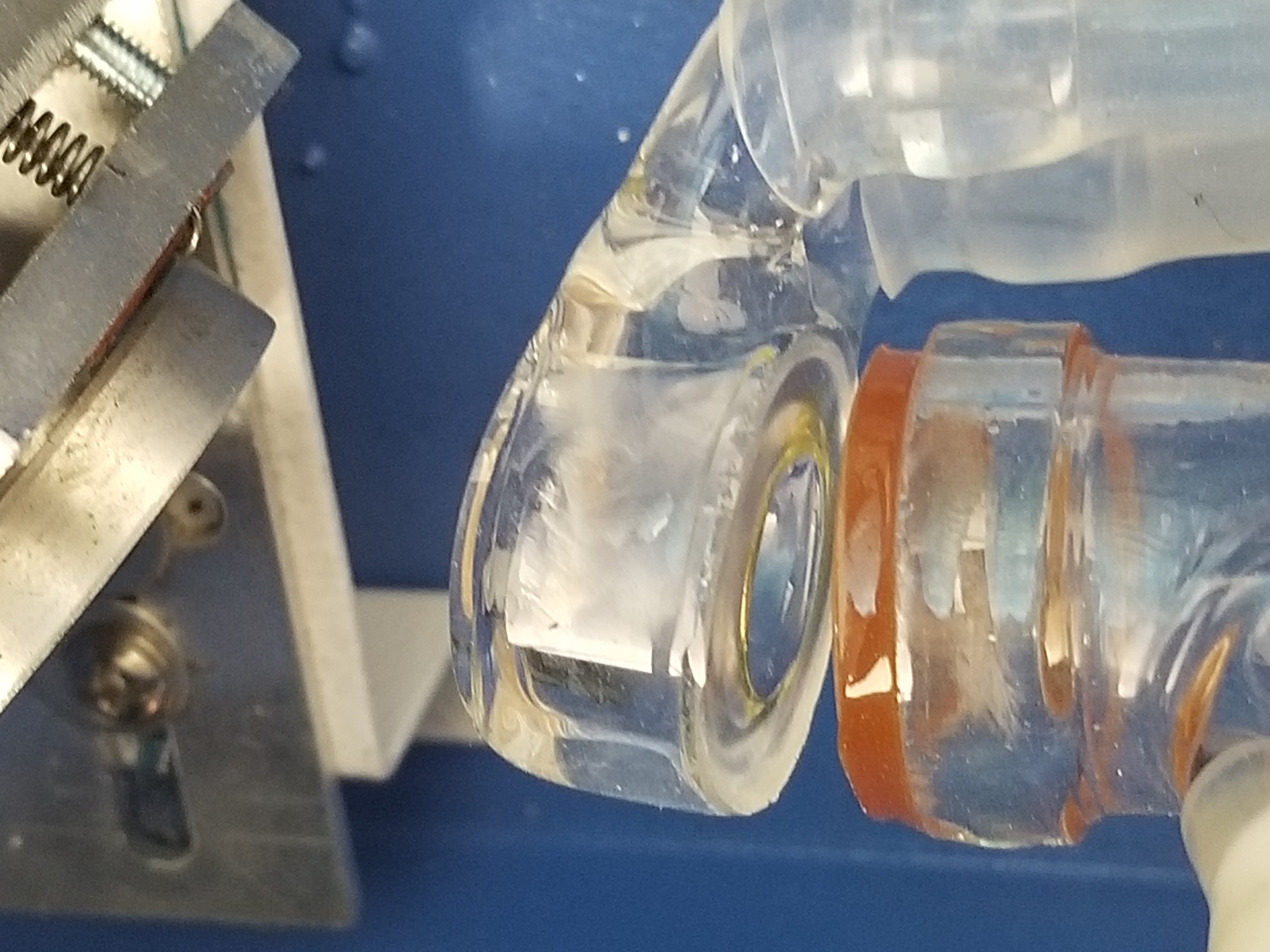

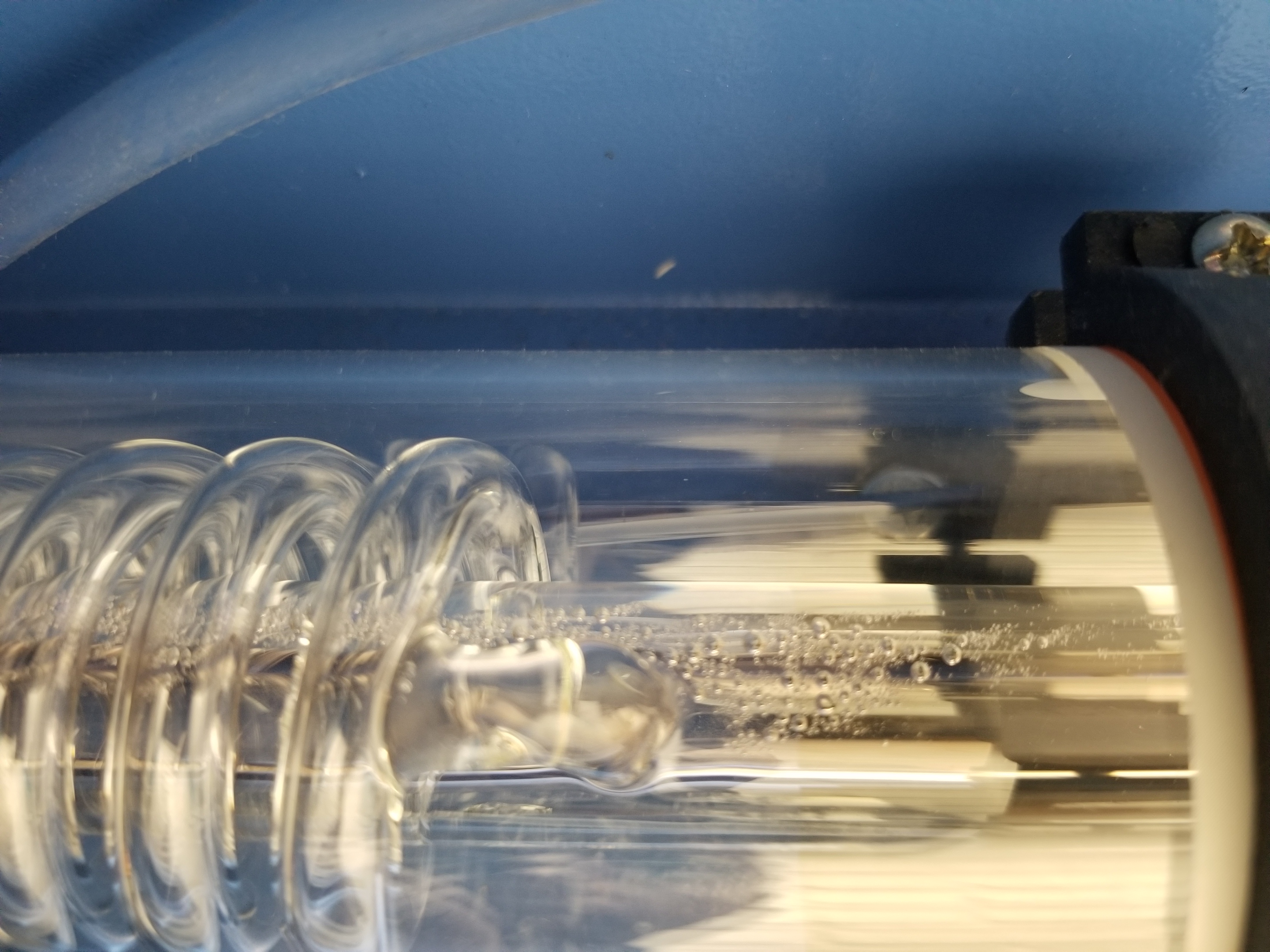

In my case, my output lens/mirror part of the tube broke (no visual clues) somehow the air bubbles trapped in the output part of the tube (where the lens/mirror sits) caused it to malfunction (heat?) despite the tube glowing when fired.

Hope this helps,

Cheers Paul

Okay, this can be caused by many things. I normally check the lens and mirrors. A speck of dust or debris from a previous laser job can drop the power considerably.

Also check the wiring (pwm/ground) and for loose screw terminals on the power supply.

Ideally you should keep a log of hours ran on the tube. They last for about 1000 hours although better quality brands last longer.

In my case, my output lens/mirror part of the tube broke (no visual clues) somehow the air bubbles trapped in the output part of the tube (where the lens/mirror sits) caused it to malfunction (heat?) despite the tube glowing when fired.

Hope this helps,

Cheers Paul

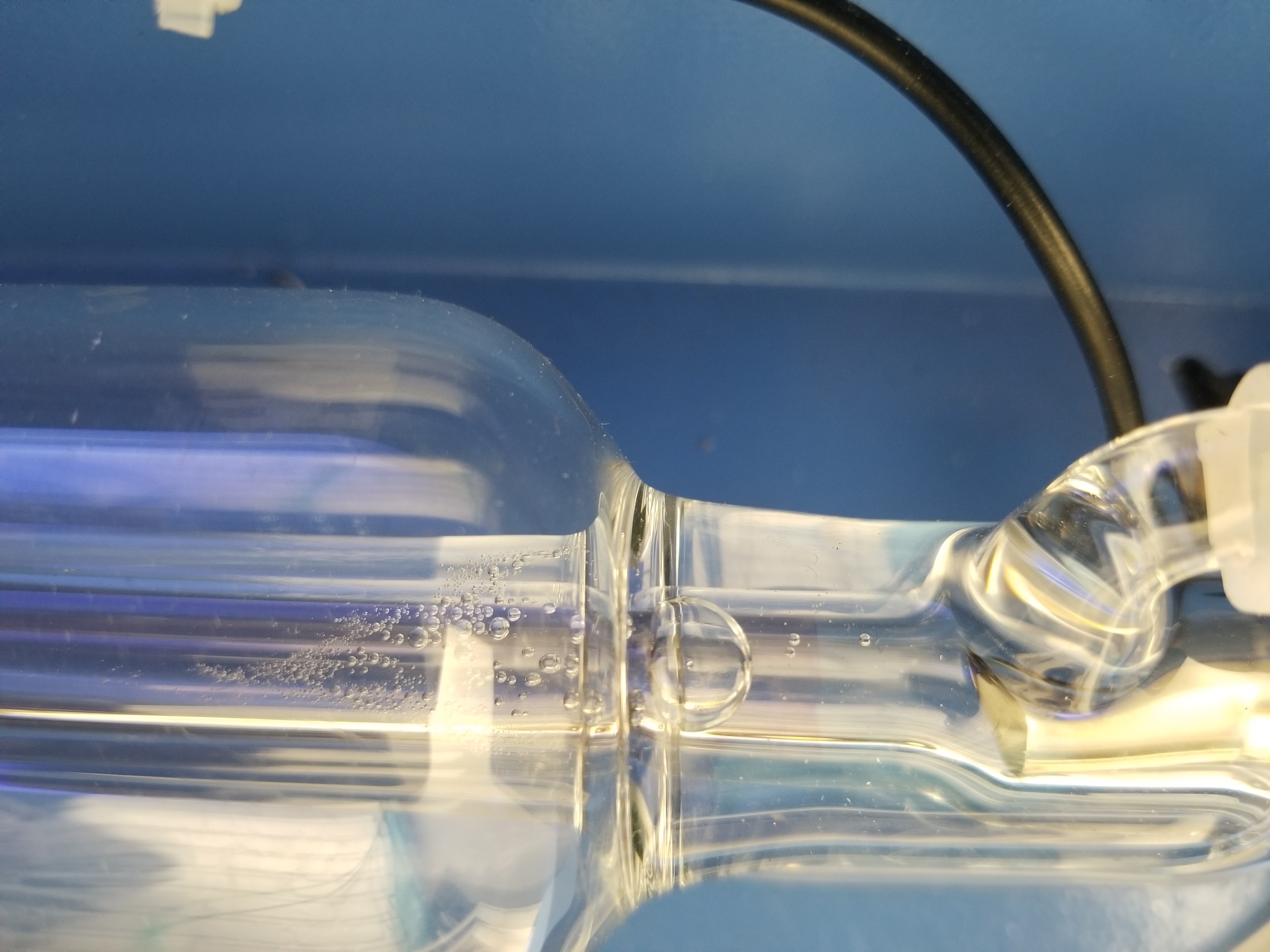

Quote from Flex1 on July 1, 2019, 6:45 amPaul, is my recently discovered "tube break" similar to what you experienced?

I've attached a photo of what was discovered while I was inspecting my laser tube.

It appears that the output end of the laser tube separated (broke?) from the lens. I'm not exactly sure when it happened, but I'm suspecting it was right before I started to noticed the laser's power loss. Now from what I can tell, it looks like the "tube end piece" was dangling and obstructing the beams path to the 1st mirror on my laser (see attached photo).

I've since re-attached the tube end with 30 min epoxy, but the power level is still very discouraging. I can't get the laser to cut through 1/8" acrylic at it's highest power/slowest speed.

My best guess is I may need to purchase and replace my laser tube, even if it's still emitting a beam during firing (see attached photo)

I've researched, double checked the wiring connections and power supply. The fact that I only have less than 10 hours on this machine has me stomped with the actual diagnosis.

Paul, is my recently discovered "tube break" similar to what you experienced?

I've attached a photo of what was discovered while I was inspecting my laser tube.

It appears that the output end of the laser tube separated (broke?) from the lens. I'm not exactly sure when it happened, but I'm suspecting it was right before I started to noticed the laser's power loss. Now from what I can tell, it looks like the "tube end piece" was dangling and obstructing the beams path to the 1st mirror on my laser (see attached photo).

I've since re-attached the tube end with 30 min epoxy, but the power level is still very discouraging. I can't get the laser to cut through 1/8" acrylic at it's highest power/slowest speed.

My best guess is I may need to purchase and replace my laser tube, even if it's still emitting a beam during firing (see attached photo)

I've researched, double checked the wiring connections and power supply. The fact that I only have less than 10 hours on this machine has me stomped with the actual diagnosis.

Uploaded files:Quote from Paul on July 1, 2019, 11:16 amHi, indeed I did encounter the same issue. The end bit contains the output lens and it's almost impossible to align it properly while glue-ing it back.

I suggest to replace the tube. Note they only last about 1000 hours although you can get lucky. The production standards in China are pretty low (search on YouTube for chinese laser factory https://www.youtube.com/watch?v=paUslNuKgLo, lol).

Best is to search ebay for $180-250 range and confirm the packing and transport options or find a local supplier. Note tubes have a limited storage/expiry date. Apparently the gas slowly deteriorates while in storage, that's why they date the tubes.

Cheers, Paul

Hi, indeed I did encounter the same issue. The end bit contains the output lens and it's almost impossible to align it properly while glue-ing it back.

I suggest to replace the tube. Note they only last about 1000 hours although you can get lucky. The production standards in China are pretty low (search on YouTube for chinese laser factory https://www.youtube.com/watch?v=paUslNuKgLo, lol).

Best is to search ebay for $180-250 range and confirm the packing and transport options or find a local supplier. Note tubes have a limited storage/expiry date. Apparently the gas slowly deteriorates while in storage, that's why they date the tubes.

Cheers, Paul

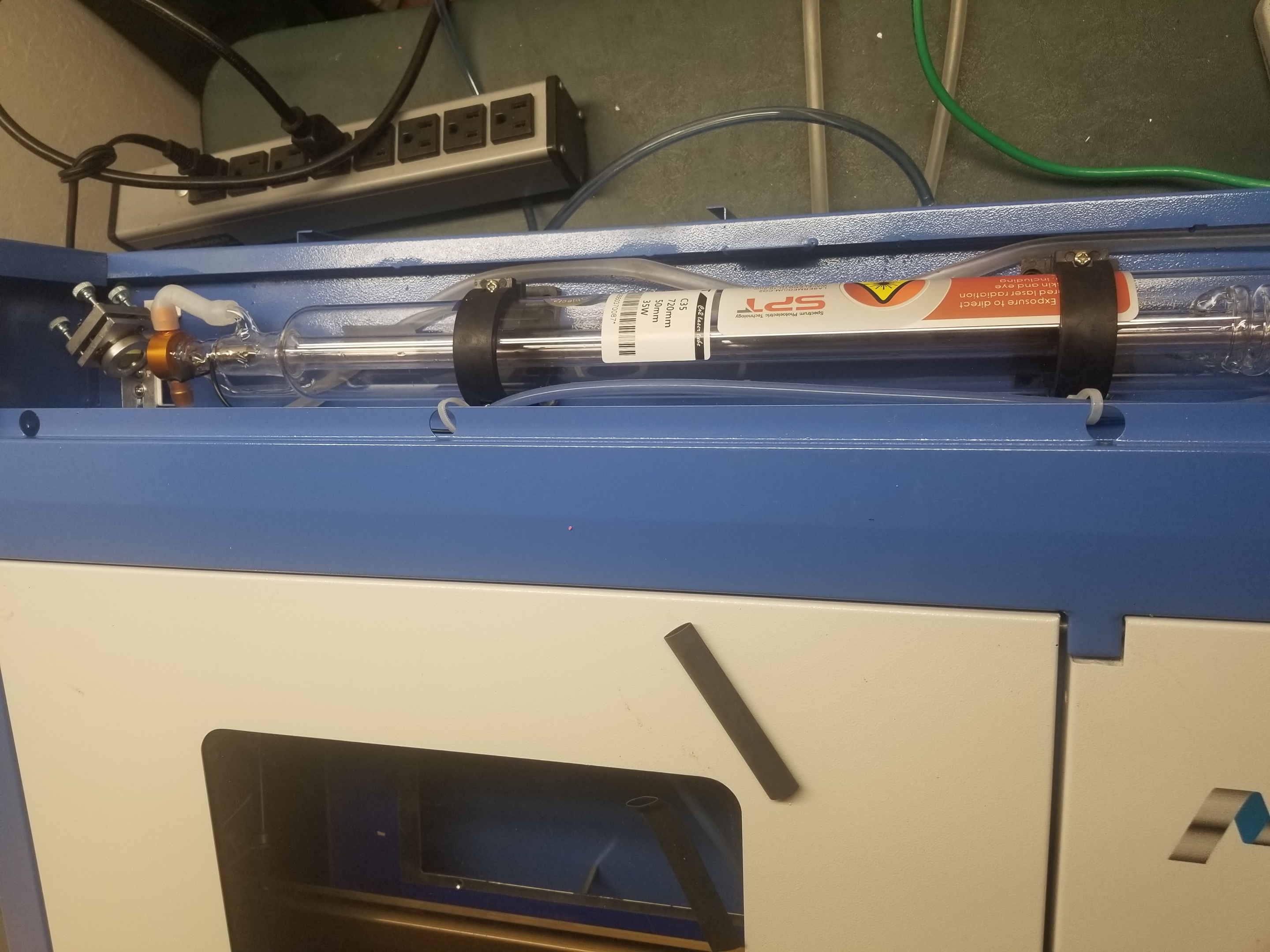

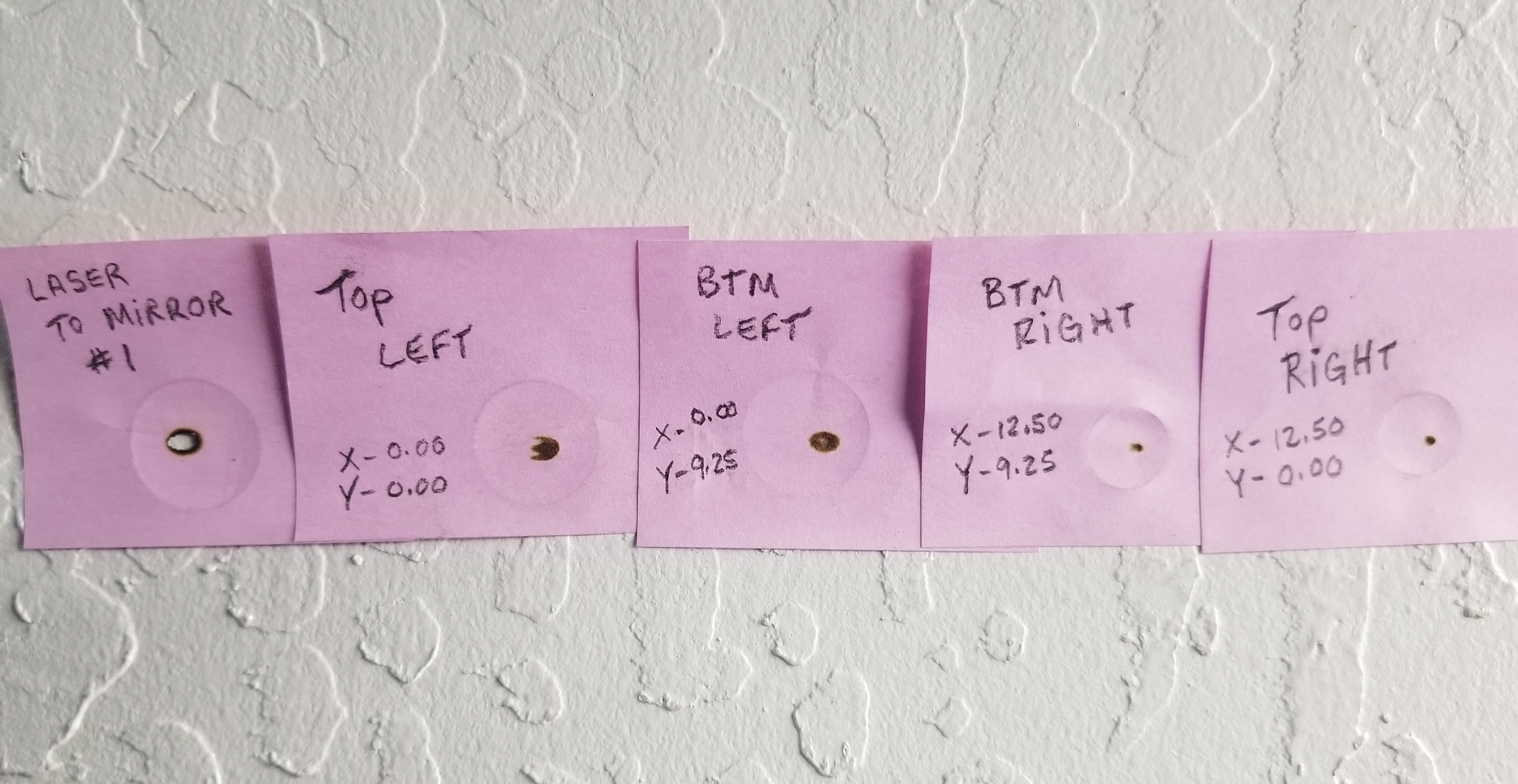

Quote from Flex1 on July 7, 2019, 12:50 amPaul, I would like to thank you for your support. Your suggestions were extremely helpful and exactly what was needed. On 7/1/19 I ordered a replacement tube from a local supplier. To my surprise, the tube arrived the very next day on 7/2/2019. I researched laser tube removal/installation for 2 days (7/2/19 & 7/3/19) until I felt confident doing the exchange. My first physical task was to add a "2-way" switch which allowed me to use the "Test Fire" button on my K40 (for aligning the mirrors later in the procedure). Next I installed the new laser tubes and made final electrical connections. I then spent 1 day researching many mirror alignment procedures until I felt comfortable with the challenge. After several hours of trial an error, I finally got all of the mirrors aligned and the laser firing properly. I took a break for a day to celebrate Independence Day 7/4/2019. On 7/5/19 I had to experiment with the power settings (I now have more power than ever before). The original tube must have been on its last days when I first received it. Now I'm up and running consistent for the first time since owning my machine. It was all made possible because of this forum and of course our savor "Paul". I still have some tweaks to do, but I have to read and learn how to perform them. I'm totally confident I will be successful with the help of this site and Paul's input. I attached a couple of photos and I hope this thread can helps someone like it has me. Thank You!

Paul, I would like to thank you for your support. Your suggestions were extremely helpful and exactly what was needed. On 7/1/19 I ordered a replacement tube from a local supplier. To my surprise, the tube arrived the very next day on 7/2/2019. I researched laser tube removal/installation for 2 days (7/2/19 & 7/3/19) until I felt confident doing the exchange. My first physical task was to add a "2-way" switch which allowed me to use the "Test Fire" button on my K40 (for aligning the mirrors later in the procedure). Next I installed the new laser tubes and made final electrical connections. I then spent 1 day researching many mirror alignment procedures until I felt comfortable with the challenge. After several hours of trial an error, I finally got all of the mirrors aligned and the laser firing properly. I took a break for a day to celebrate Independence Day 7/4/2019. On 7/5/19 I had to experiment with the power settings (I now have more power than ever before). The original tube must have been on its last days when I first received it. Now I'm up and running consistent for the first time since owning my machine. It was all made possible because of this forum and of course our savor "Paul". I still have some tweaks to do, but I have to read and learn how to perform them. I'm totally confident I will be successful with the help of this site and Paul's input. I attached a couple of photos and I hope this thread can helps someone like it has me. Thank You!

Uploaded files:Quote from Paul on July 7, 2019, 9:03 amThanks Flex1, such a great response is very satisfying and I am glad you got it to work well!

In stead of a physical three way switch, you can actually set up a macro in LightBurn that switches the controller to cnc mode which allows test fires while the gantry is stationary.

Right click on the macro and enter a name and populate it with the $ settings and G-code commands as following (without the commentary):

$32=0 (to cnc mode)

S200 (strength 4 mA)

M3 (or M4 to switch on the LO connection)

G4 P1000 (or longer, dwell or pause command)

M5 (switch LO off)

$32=1 (restore to laser mode)

So when you click on the macro, it test fires for 1 sec which leaves a make on the tape that you use to cover a mirror. Start from tube mirror and move toward the end (gantry). Adjust the mirrors and repeat across four corners of the laser. It's tedious and it can take a few hours to get an alignment.

Note: If you cannot align it but got a movement of a mm, don't worry too much. Anything more out of alignment indicates of a skewed gantry which can be solved by shims, washers or partly rebuilds...

Cheers!

Thanks Flex1, such a great response is very satisfying and I am glad you got it to work well!

In stead of a physical three way switch, you can actually set up a macro in LightBurn that switches the controller to cnc mode which allows test fires while the gantry is stationary.

Right click on the macro and enter a name and populate it with the $ settings and G-code commands as following (without the commentary):

$32=0 (to cnc mode)

S200 (strength 4 mA)

M3 (or M4 to switch on the LO connection)

G4 P1000 (or longer, dwell or pause command)

M5 (switch LO off)

$32=1 (restore to laser mode)

So when you click on the macro, it test fires for 1 sec which leaves a make on the tape that you use to cover a mirror. Start from tube mirror and move toward the end (gantry). Adjust the mirrors and repeat across four corners of the laser. It's tedious and it can take a few hours to get an alignment.

Note: If you cannot align it but got a movement of a mm, don't worry too much. Anything more out of alignment indicates of a skewed gantry which can be solved by shims, washers or partly rebuilds...

Cheers!

Quote from Flex1 on July 9, 2019, 4:54 pmPaul,

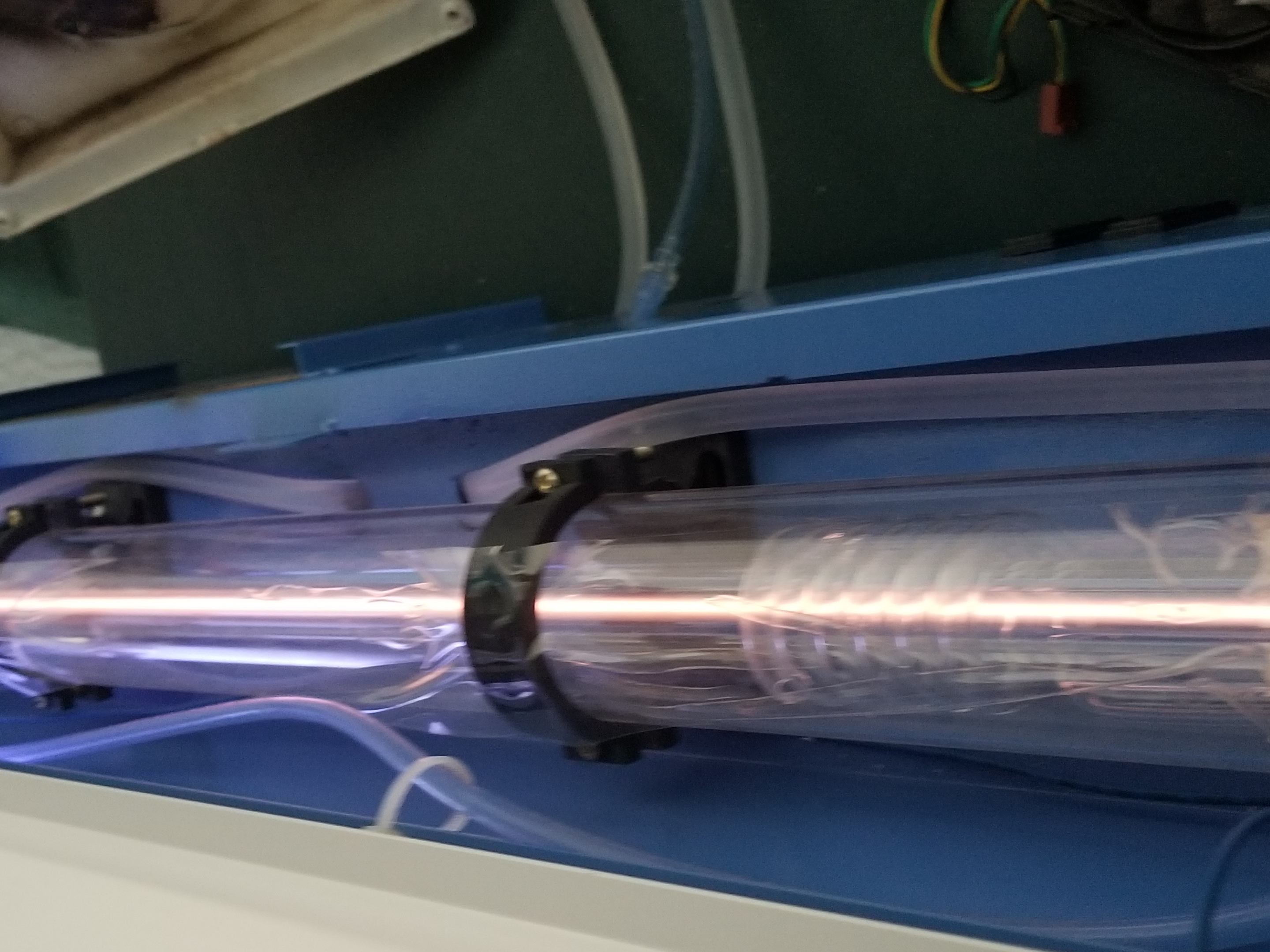

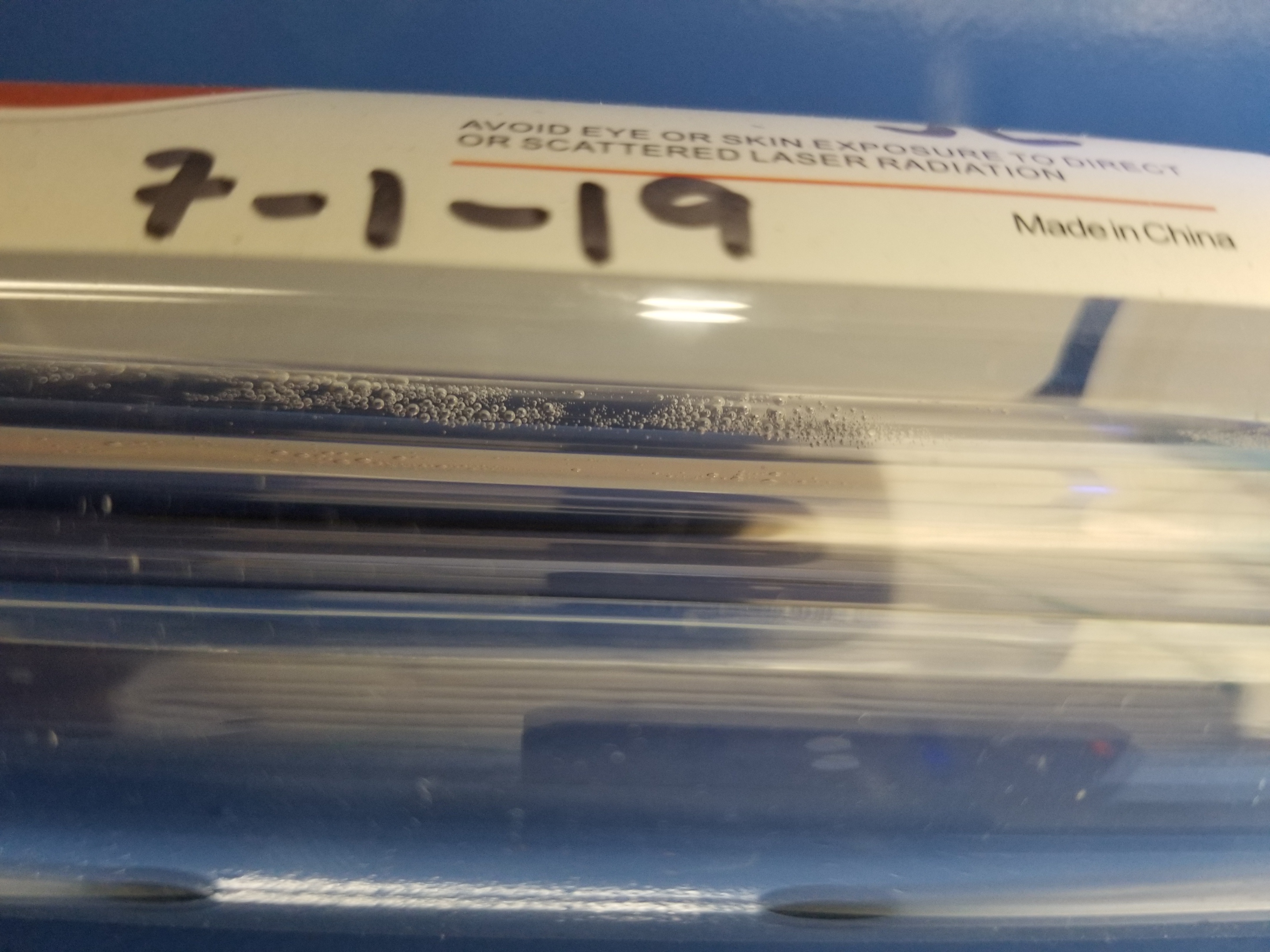

I need your opinion on what I believe to a laser tube problem with my newly installed laser tube. The new tube only has approx. 5 hours actual laser time and it was working fine a few days ago. Yesterday I started noticing the lack of laser power with known successful program settings. I just had to replace my original K40 laser tube about a week ago for the same exact symptoms. My best guess is something is wreaking havoc on my laser tubes. Today I opened the back of my K40 and noticed small air bubbles along the length of the tube. I attached photos of what I saw in the tube and the mirror alignment results I did right after noticing the lack of power. The bubble may be the root cause, but I'm new to this and I'm not really sure. If I have to spend another $235 for another laser tube, I definitely need to research as many possibilities as possible, because the cost of two tubes will be more than a brand new K40. I really need help figuring this out before it cost me a small fortune.

Here is a list of things that may aid your opinion consideration:

- I engraved a Tiger photo that took 184 mins. straight and the water temp was never above 23c

- I hang my water outlet hose above the water supply bucket so I can hear the water flowing back in the bucket during operation (audible indicator).

- Water pump circulation appears to be good. I see solid stream returning with no visual air bubbles in the tubing.

- I never checked for bubble my old laser tube before, so I'm not sure if the heat from unknown bubbles may have caused the cooling tip to come off, thus causing the failure.

- I rotated the new tube a day ago because I saw a larger bubble at the outlet side of the tube when aligning mirrors. Once rotated the tube was free of all bubble incl, small ones.

- I cleaned all mirrors and lenses and still experienced low power

- I created the "Test Fire" macro you suggested and it worked perfectly, so I tried realigning the mirrors and it hasn't performed since.

- Example of power loss is before I could cut 3mm acrylic 1 pass at 0.10 in./s, 40% max power and 75% power scale. Now it takes 6-7 passes at 0.05 in/s, 40% max power and 100% power scale.

Thanks in advance.

Paul,

I need your opinion on what I believe to a laser tube problem with my newly installed laser tube. The new tube only has approx. 5 hours actual laser time and it was working fine a few days ago. Yesterday I started noticing the lack of laser power with known successful program settings. I just had to replace my original K40 laser tube about a week ago for the same exact symptoms. My best guess is something is wreaking havoc on my laser tubes. Today I opened the back of my K40 and noticed small air bubbles along the length of the tube. I attached photos of what I saw in the tube and the mirror alignment results I did right after noticing the lack of power. The bubble may be the root cause, but I'm new to this and I'm not really sure. If I have to spend another $235 for another laser tube, I definitely need to research as many possibilities as possible, because the cost of two tubes will be more than a brand new K40. I really need help figuring this out before it cost me a small fortune.

Here is a list of things that may aid your opinion consideration:

- I engraved a Tiger photo that took 184 mins. straight and the water temp was never above 23c

- I hang my water outlet hose above the water supply bucket so I can hear the water flowing back in the bucket during operation (audible indicator).

- Water pump circulation appears to be good. I see solid stream returning with no visual air bubbles in the tubing.

- I never checked for bubble my old laser tube before, so I'm not sure if the heat from unknown bubbles may have caused the cooling tip to come off, thus causing the failure.

- I rotated the new tube a day ago because I saw a larger bubble at the outlet side of the tube when aligning mirrors. Once rotated the tube was free of all bubble incl, small ones.

- I cleaned all mirrors and lenses and still experienced low power

- I created the "Test Fire" macro you suggested and it worked perfectly, so I tried realigning the mirrors and it hasn't performed since.

- Example of power loss is before I could cut 3mm acrylic 1 pass at 0.10 in./s, 40% max power and 75% power scale. Now it takes 6-7 passes at 0.05 in/s, 40% max power and 100% power scale.

Thanks in advance.

Uploaded files:Quote from Flex1 on July 22, 2019, 5:28 amYesterday, I replaced my 16L/min water pump with a 20L water pump. I think the older water pump was failing thus causing the original tube failure. Now the new 35W laser tube is free of bubble. Mirror alignment was done and now I have new problem.

Has anyone ever seen or experienced this failure? If so, what was the cause and how was it resolved.

Thanks in advance.

Yesterday, I replaced my 16L/min water pump with a 20L water pump. I think the older water pump was failing thus causing the original tube failure. Now the new 35W laser tube is free of bubble. Mirror alignment was done and now I have new problem.

Has anyone ever seen or experienced this failure? If so, what was the cause and how was it resolved.

Thanks in advance.

Uploaded files:Quote from Paul on August 3, 2019, 8:51 amAlways try to keep the mirrors as clean as possible. A speck of dirt can heat up and crack the mirror. Best is to use good quality MO mirrors and clean them after each heavy cutting activity.

Always try to keep the mirrors as clean as possible. A speck of dirt can heat up and crack the mirror. Best is to use good quality MO mirrors and clean them after each heavy cutting activity.

Quote from Keith1018 on December 31, 2019, 5:29 amI had the same issue as FLEX1 with the end of the tube dangling. I was able to fix it and it was working great until a few days ago. The way I repaired it was to take it out and stand it up vertical, and carefully put some glass glue or superglue around the outside edges. But do this with extreme care so you don't get any on the internal lens, it makes it very difficult to clean.

Also had the same issue with AIR BUBBLEs in the tube, I was able to remove them by ensuring that the tube is at a position so the bends and connections are on the bottom, or at least on the extreme side. This ensures the water flows better and doesn't allow air bubbles.

I had the same issue as FLEX1 with the end of the tube dangling. I was able to fix it and it was working great until a few days ago. The way I repaired it was to take it out and stand it up vertical, and carefully put some glass glue or superglue around the outside edges. But do this with extreme care so you don't get any on the internal lens, it makes it very difficult to clean.

Also had the same issue with AIR BUBBLEs in the tube, I was able to remove them by ensuring that the tube is at a position so the bends and connections are on the bottom, or at least on the extreme side. This ensures the water flows better and doesn't allow air bubbles.