poor quality engraving

Quote from Rommel1787 on September 30, 2019, 3:52 amHI

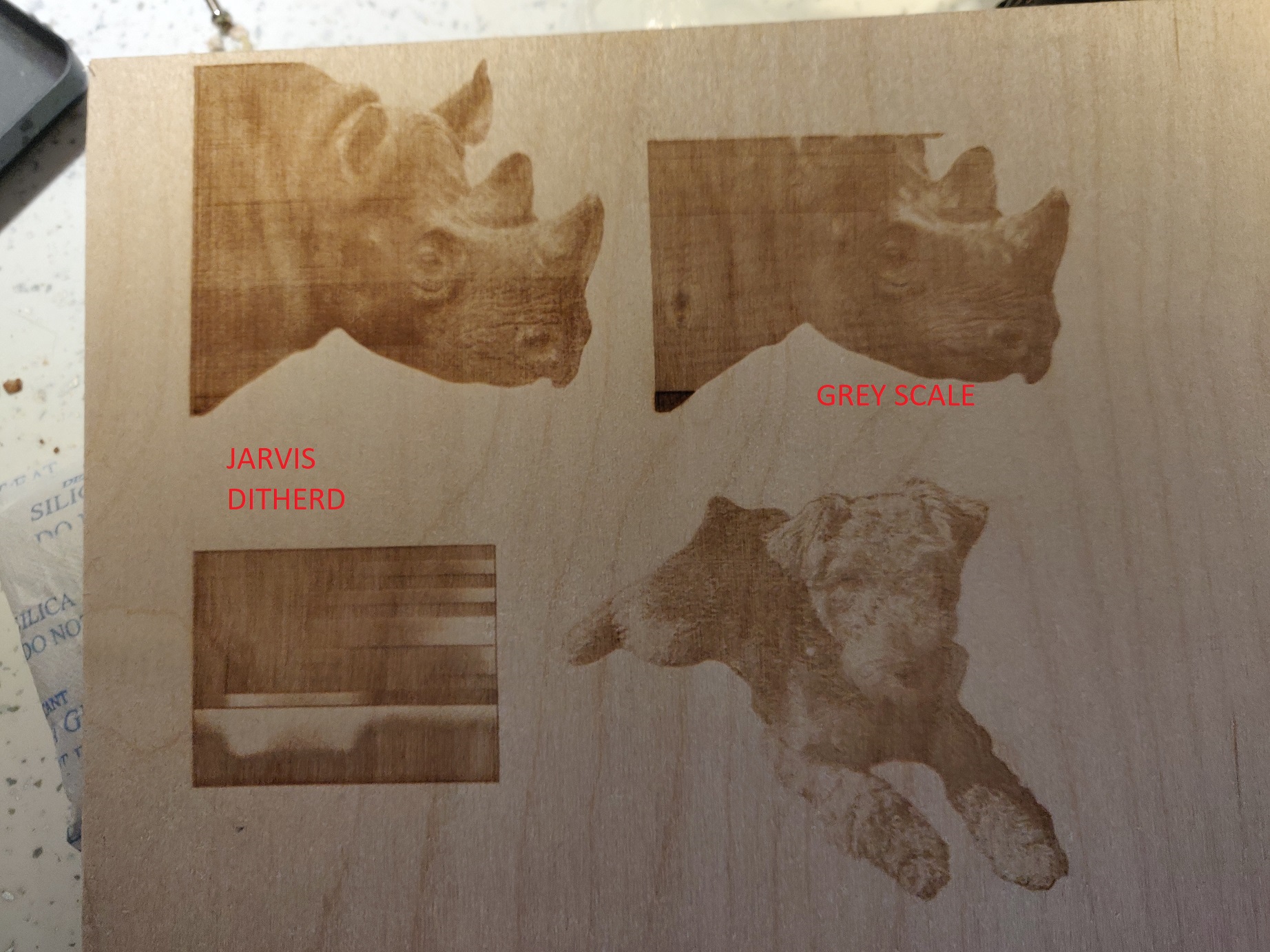

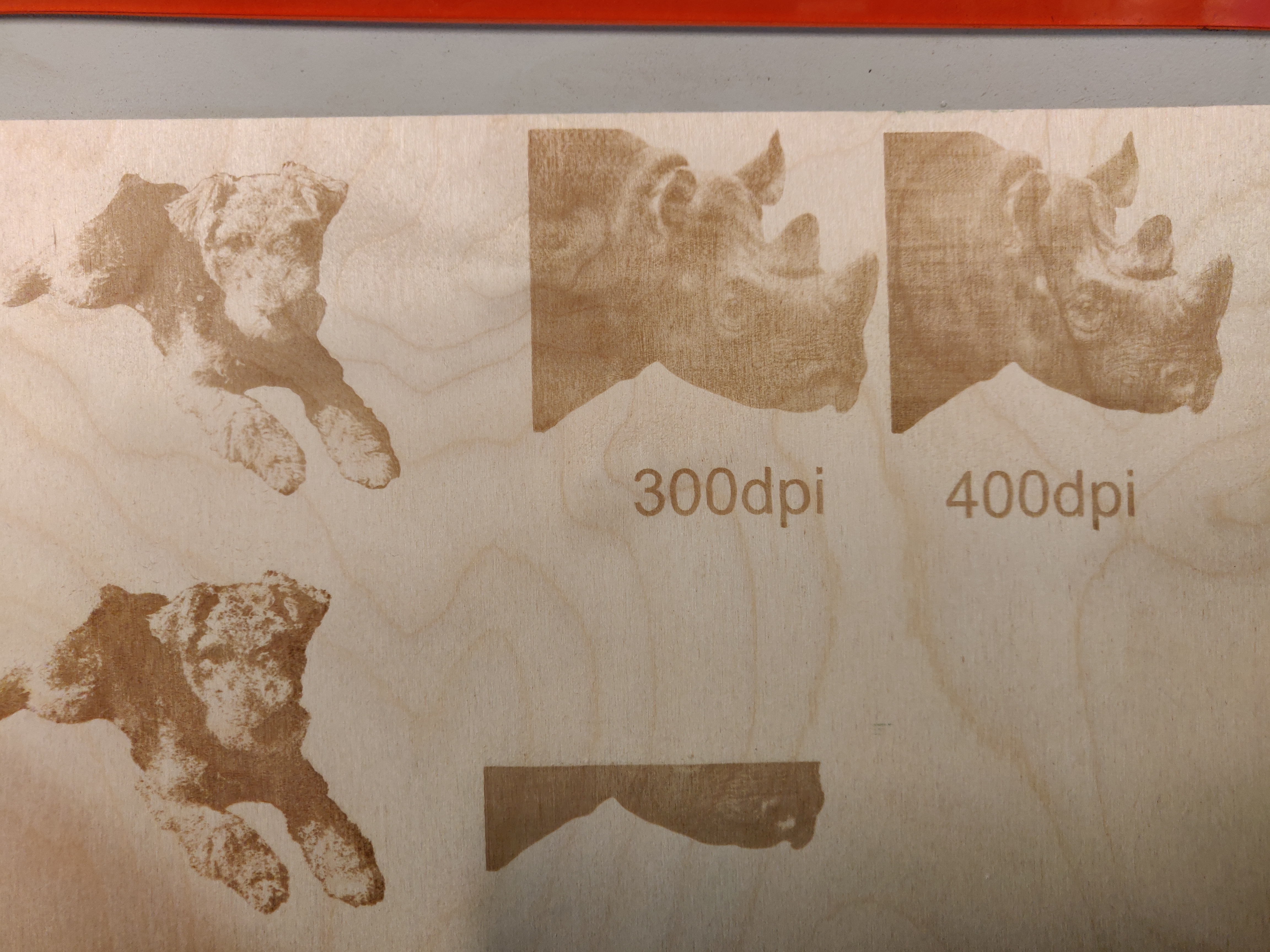

Im realllly struggling to get good images engraved. ive wasted so much wood trying. can anyone check my settings and maybe compare your engravings to mine. ive attached photos.

$$

$0=10

$1=255

$2=0

$3=1

$4=0

$5=1

$6=0

$7=0

(ATC M6, pulse/ff)

$8=100

(ATC Tool Td, milliseconds)

$9=100

(ATC M6 Td, milliseconds)

$10=31

$11=0.010

$12=0.002

$13=0

$19=0

(Softstart, milliseconds)

$20=0

$21=0

$22=1

$23=3

$24=2000.000

$25=2000.000

$26=250

$27=2.500

$28=5

(Spindle freq. 0 to 15)

$30=2000

$31=1

$32=1

$100=157.000

(x:stp/mm)

$101=157.000

(y:stp/mm)

$102=160.000

(z:stp/mm)

$103=160.000

(a:stp/mm)

$104=160.000

(b:stp/mm)

$110=12000.000

(x:mm/min)

$111=5000.000

(y:mm/min)

$112=5000.000

(z:mm/min)

$113=5000.000

(a:mm/min)

$114=5000.000

(b:mm/min)

$120=8000.000

(x:mm/s^2)

$121=3000.000

(y:mm/s^2)

$122=3000.000

(z:mm/s^2)

$123=3000.000

(a:mm/s^2)

$124=3000.000

(b:mm/s^2)

$130=230.000

(x:mm max)

$131=320.000

(y:mm max)

$132=200.000

(z:mm max)

$133=200.000

(a:mm max)

$134=200.000

(b:mm max)

Im using Lightburn software

HI

Im realllly struggling to get good images engraved. ive wasted so much wood trying. can anyone check my settings and maybe compare your engravings to mine. ive attached photos.

$$

$0=10

$1=255

$2=0

$3=1

$4=0

$5=1

$6=0

$7=0

(ATC M6, pulse/ff)

$8=100

(ATC Tool Td, milliseconds)

$9=100

(ATC M6 Td, milliseconds)

$10=31

$11=0.010

$12=0.002

$13=0

$19=0

(Softstart, milliseconds)

$20=0

$21=0

$22=1

$23=3

$24=2000.000

$25=2000.000

$26=250

$27=2.500

$28=5

(Spindle freq. 0 to 15)

$30=2000

$31=1

$32=1

$100=157.000

(x:stp/mm)

$101=157.000

(y:stp/mm)

$102=160.000

(z:stp/mm)

$103=160.000

(a:stp/mm)

$104=160.000

(b:stp/mm)

$110=12000.000

(x:mm/min)

$111=5000.000

(y:mm/min)

$112=5000.000

(z:mm/min)

$113=5000.000

(a:mm/min)

$114=5000.000

(b:mm/min)

$120=8000.000

(x:mm/s^2)

$121=3000.000

(y:mm/s^2)

$122=3000.000

(z:mm/s^2)

$123=3000.000

(a:mm/s^2)

$124=3000.000

(b:mm/s^2)

$130=230.000

(x:mm max)

$131=320.000

(y:mm max)

$132=200.000

(z:mm max)

$133=200.000

(a:mm max)

$134=200.000

(b:mm max)

Im using Lightburn software

Uploaded files:Quote from Paul on September 30, 2019, 7:43 amHi the $30 $ setting needs to be 1000 (power range). If you set it to 2000 then a S parm of 255 with be 1/8th of the laser power. While a power range of 1000 gives this 1/4th of the power range.

When setting the $ setting in the Mini, make sure that the S parm in Light Burn is set to the same value. This is available in Device settings.

Hi the $30 $ setting needs to be 1000 (power range). If you set it to 2000 then a S parm of 255 with be 1/8th of the laser power. While a power range of 1000 gives this 1/4th of the power range.

When setting the $ setting in the Mini, make sure that the S parm in Light Burn is set to the same value. This is available in Device settings.

Uploaded files:Quote from Rommel1787 on October 1, 2019, 7:26 amHi

My $28 is 2000 at the moment but it is set it LB to 2000.

I have changed the $28 to 1000 and set the S value in LB to match. Re ran the test and the results looks some what the same

Hi

My $28 is 2000 at the moment but it is set it LB to 2000.

I have changed the $28 to 1000 and set the S value in LB to match. Re ran the test and the results looks some what the same

Uploaded files:

Quote from Paul on November 9, 2019, 7:56 amHi, how old is the tube? They last about 800-1000 hours but my first tube was already weak from day one. After replacing it with a reci tube, it finally was able to cut plywood.

Also you can experiment with lower values like 500 and see if it improves. Lower values means a smaller range and is a good indicator that the tube has lost power.

Hi, how old is the tube? They last about 800-1000 hours but my first tube was already weak from day one. After replacing it with a reci tube, it finally was able to cut plywood.

Also you can experiment with lower values like 500 and see if it improves. Lower values means a smaller range and is a good indicator that the tube has lost power.

Quote from Devo on November 26, 2019, 4:01 pmI had similar issues with gray scale in the beginning. I stopped using the post process in lightburn (jarvis,stuki,dither etc) and started editing within coreldraw to suit my laser (proper photo prep IS CRITICAL) then i use the pass-through option and my results have been nothing short of amazing.

I had similar issues with gray scale in the beginning. I stopped using the post process in lightburn (jarvis,stuki,dither etc) and started editing within coreldraw to suit my laser (proper photo prep IS CRITICAL) then i use the pass-through option and my results have been nothing short of amazing.