While ‘Dither vs Gray scale’ sounds like a movie, it’s the question K40 laser engravers ask themselves every day. I recently got a question on FaceBook asking me what the difference is between dither and pwm (he meant ‘gray scale’) engraving.

In a nutshell:

The pulse width modulation (pwm) signal used for gray scale engraving is seen by the laser power supply driver as an average input voltage level. So it seems like an analogue signal while dither is really creating dots per inch or mm via a fixed signal width on/off pulses (dots).

according to Luap ed Toorg

But this technical explanation has something missing… which one is better and which is faster? When to use what? Let’s test them both out.

My settings

I selected birch aeroplane plywood as my material and LightBurn as the laser engraving software since it’s easy to set-up. Dither settings were 3000mm/min, while gray scale used 1500mm/min. Gray scale is slower because the PWM generation is more complex for the controller. The picture size was 30mm x 50mm.

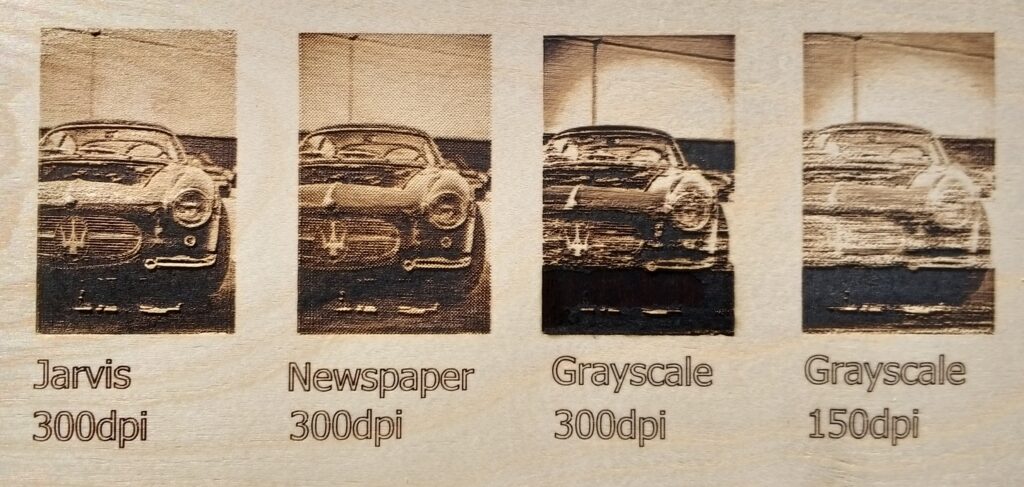

Comparing the look of Dither vs Gray Scale

The Jarvis dither pattern achieves more contrast and seems more realistic than the Newspaper dither pattern.

The interesting thing is that Gray scale is very disappointing in comparison to the dither options. I’ve previously had great results with Gray scale, so what’s going on here? My hypothesis is that scaling down the picture size causes ‘artefacts’ – various interference in the image. So let’s test this by enlarging and re-engraving the gray scale.

C’mon, let’s see if we can get a better gray scale out of this K40 laser…

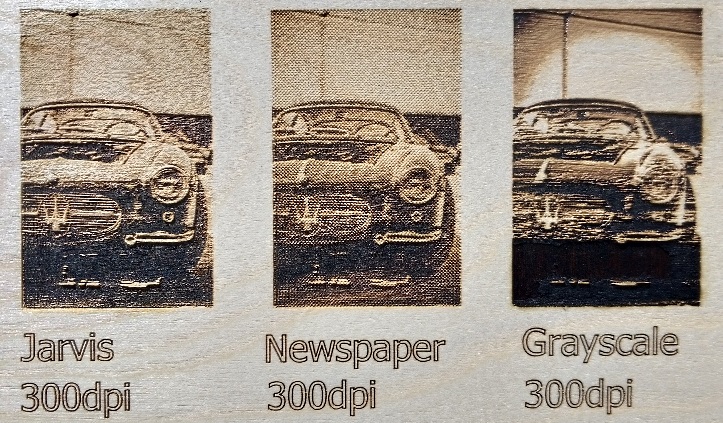

Getting gray scale right

This result is much better (the original photo had minimal detail in the under-car shadow area too). You can now see the grille’s honeycomb structure and tire thread. Clearly the engraving has benefited from a different picture and engraving resolution.

To get similar good results, I recommend you use LaserWeb’s ‘Scale optimised for best engraving’ feature. Usually it enlarges your engraving to match the available picture detail. But it’s not magic – you still need to patiently dial in your engraving settings for great results.

In general, gray scale benefits from higher resolution (such as 440 dpi) and runs at half the speed of dither. Does that make dither the preferred engraving? Well big brands like Epilogue and Trotec recommend dither to claim speed gains. Whether you prefer it is up to you !

Enjoy experimenting… to get the best results for your K40 laser, check out our Mini Gerbil controller. Head to our purchase page !

1 thought on “K40 laser: Dither or Gray scale engraving ?”