PWM and Pot

Quote from Guest on January 10, 2018, 8:45 pmHi all,

have my Gerbil installed now and run it under LaserWeb, so far for cutting only. Installation went smoothly and with LaserWeb I don't have any mirror issues. I had to configure homing direction going up left and -Y going down, the bottom end in LaserWeb I set to -225 (bed size given as 325x225). No modification of the endstops.

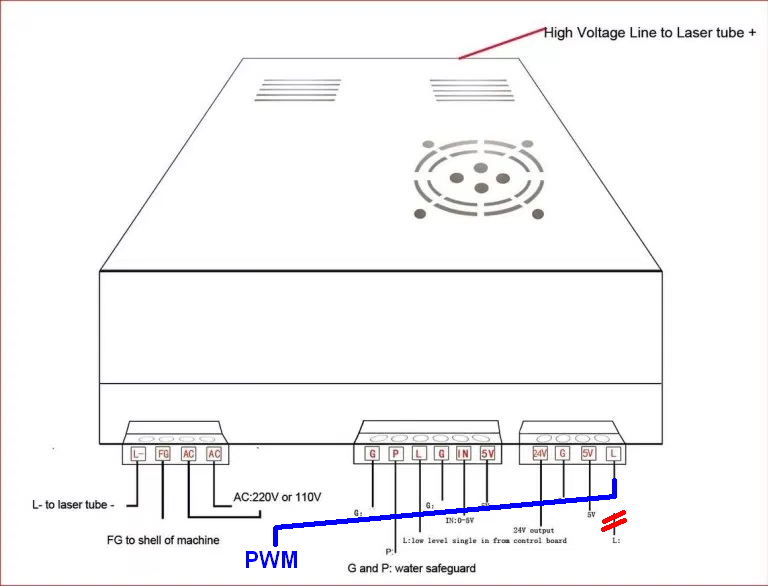

Now my question about the PWM Pin: Others (Smoothieboard e.g.) use the L-pin of the 4 pin power connector as PWM input for the PSU. Is it possible to let the L from the 4 string cable be unconnected and instead connect Gerbils PWM pin to this input? Please see the attached picture for what I mean.

THX

Hubert

Hi all,

have my Gerbil installed now and run it under LaserWeb, so far for cutting only. Installation went smoothly and with LaserWeb I don't have any mirror issues. I had to configure homing direction going up left and -Y going down, the bottom end in LaserWeb I set to -225 (bed size given as 325x225). No modification of the endstops.

Now my question about the PWM Pin: Others (Smoothieboard e.g.) use the L-pin of the 4 pin power connector as PWM input for the PSU. Is it possible to let the L from the 4 string cable be unconnected and instead connect Gerbils PWM pin to this input? Please see the attached picture for what I mean.

THX

Hubert

Uploaded files:

Quote from Paul on January 11, 2018, 6:20 amHi, the L is just the laser on signal for the powersupply. With using the pwm input, we can keep the laser tube energised during non-engraving levels which reduces the latency of the tube firing. So this has been done by purpose. Also it increases the life span of the tube.

I have done trials with the pwm laser power supply left on the potmeter and send pwm thru the LO connection which gave poor performance and not the detailed shades of grey that I was after.

you can hook up a switch between the pwm and potmeter so you can switch over to the pot to get more control while cutting. I have done this successfully. You might need to switch the M4 Gcode command for M3.

Cheers, Paul

Hi, the L is just the laser on signal for the powersupply. With using the pwm input, we can keep the laser tube energised during non-engraving levels which reduces the latency of the tube firing. So this has been done by purpose. Also it increases the life span of the tube.

I have done trials with the pwm laser power supply left on the potmeter and send pwm thru the LO connection which gave poor performance and not the detailed shades of grey that I was after.

you can hook up a switch between the pwm and potmeter so you can switch over to the pot to get more control while cutting. I have done this successfully. You might need to switch the M4 Gcode command for M3.

Cheers, Paul